The TCVH plant represents a major step forward in the Vietnamese government’s vision to establish a large-scale, modern automotive industrial complex in Quang Ninh. TC Motors has made significant investments in infrastructure, logistics, and supporting facilities to expand European car manufacturing in Vietnam. The factory covers an impressive 36.5 hectares and boasts an annual production capacity up to 120,000 vehicles. The new facility is set to become a central hub for Škoda vehicle distribution across Southeast Asia and contributes to local economic development through job creation, increased tax revenues, and the training of skilled professionals. Located in Quang Ninh, Vietnam, the TCVH automobile factory, is dedicated to producing the first Škoda automobile models in the country, including the Škoda Kushaq and Škoda Slavia. Moreover, the plant’s strategic location near Haiphong port ensures efficient logistics for importing completely knocked down (CKD) kits from Pune, India. Phase I of the plant is designed for a production rate of 13 jobs per hour (JPH) with scalability to 20 JPH in Phase II.

Efficient Execution Despite Challenges

Despite global supply chain interruptions through sheet metal processing and electrical components constraints, fluctuations in maritime transport, and extreme weather events like Super Typhoon, Dürr completed the project within 18 months. From contract signing in November 2023 to final acceptance in July 2025, the project was delivered on time and to specifications.

Recognition for Excellence

In recognition of its outstanding performance, TC Motors recently awarded Dürr China the “Excellent Supplier” title. This award highlights the collaborative spirit and technical excellence that characterized the project. “A key factor in this achievement was the effective collaboration between the teams of Dürr China and Dürr Vietnam with the TC Group, working together to ensure the project's success,” said Wang Shuo, Project Manager at Dürr Paint shop systems Engineering (Shanghai) Co., Ltd. “We are extremely proud to receive this award. It reflects the dedication and professionalism of our team, who overcame considerable challenges to deliver an advanced modern factory.”

Dürr’s technological contribution

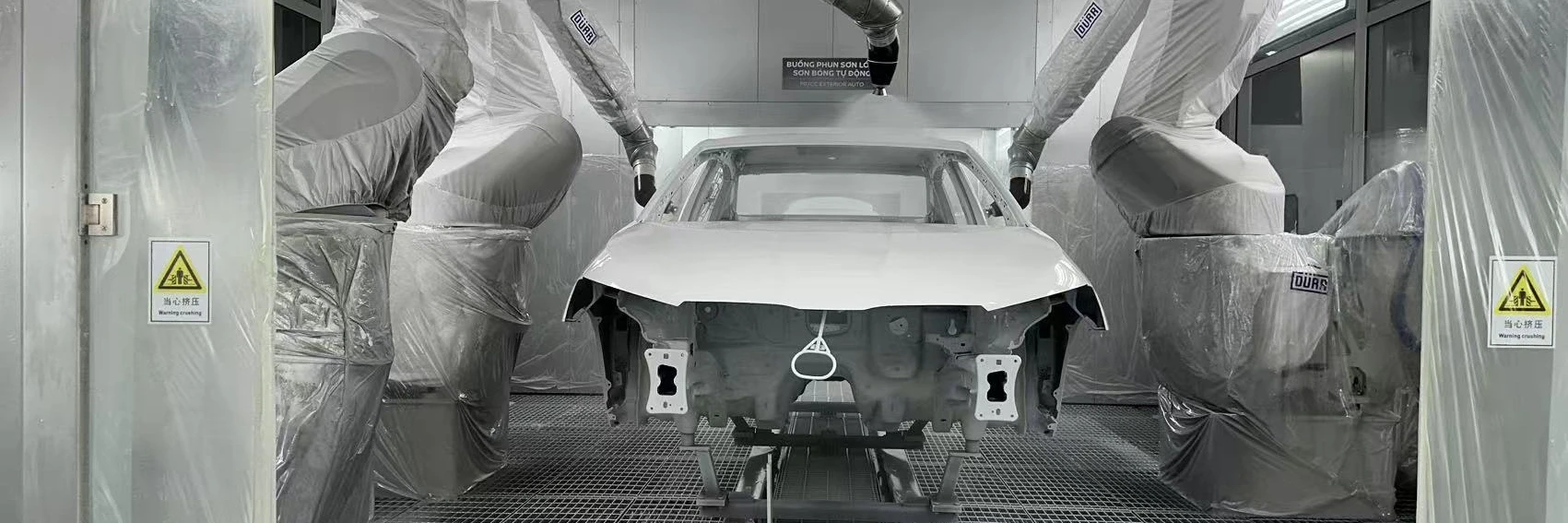

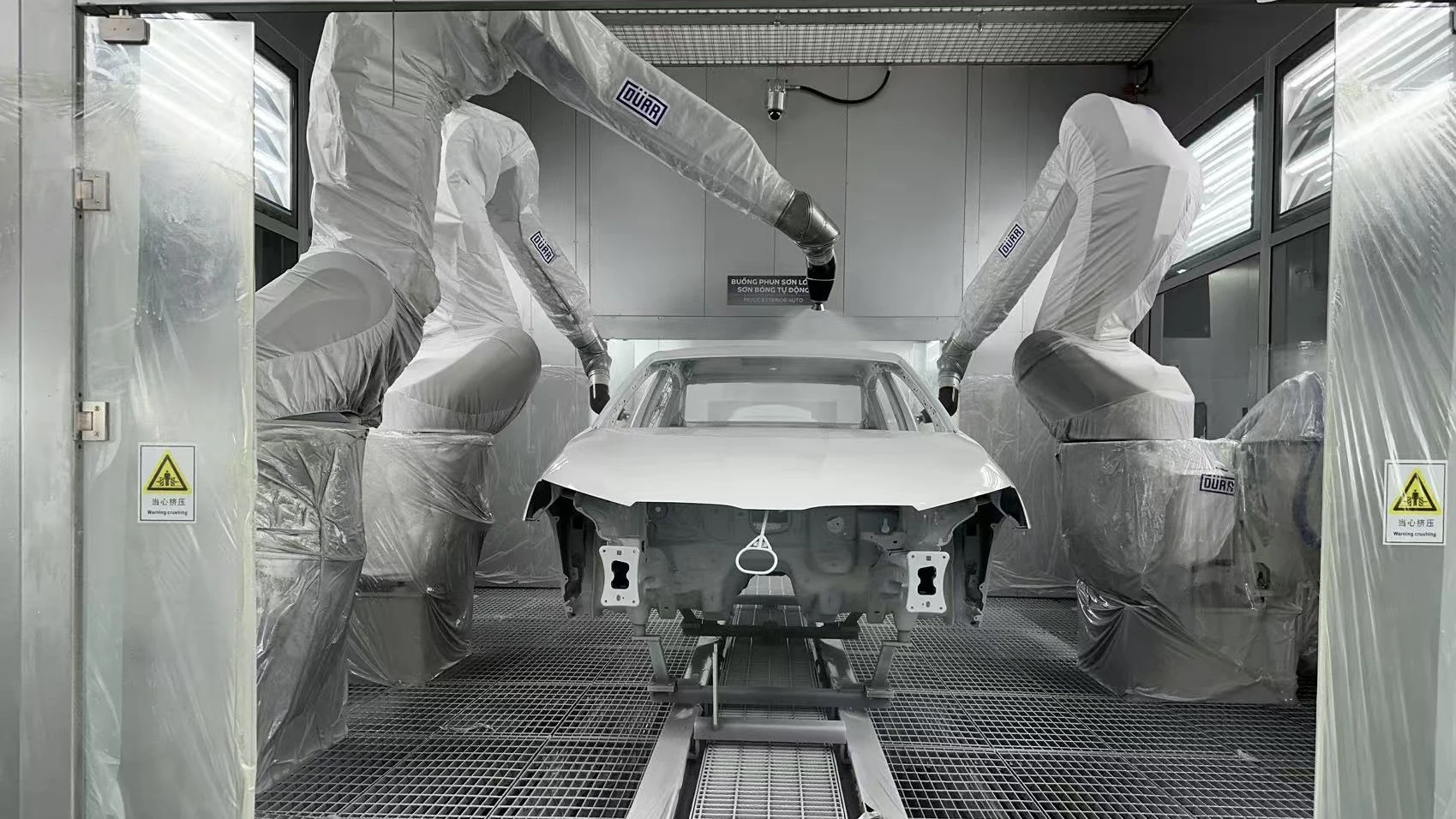

Dürr played a key role in equipping the paint shop with advanced technology. The highlight is the electrically driven RoDip® E for pretreatment and electrocoating, using freely programmable trolleys. Each trolley has a conveying drive and a rotating drive, which enable horizontal and rotating movements to be controlled independently of each other for each body.

Benefiting from this, the system can set different dip curves according to vehicle models, thereby enhancing coating quality, improving energy efficiency, and reducing unit costs. Another special feature of the paint shop is that the primer and clear coat are applied in the same spray booth. This saves investment costs. The scope of delivery also includes sealing lines, seven painting robots, ovens, and a hot wax line.