“What manufacturers need most these days from the painting process is flexibility, cost efficiency, and sustainability. We answer this need with our concept of the paint shop of the future, which overcomes the limitations of the inflexible production line. Instead, the 120 or so individual operations are executed in scalable modules or small sections, in parallel and timed precisely to the needs of the individual body,” explains Jochen Weyrauch, CEO of Dürr. This makes it easy to extend capacities and channel different vehicle types through the painting process. Ideally, even individual items can be handled while production is underway. Dürr showcased the variable configuration from pretreatment to seam sealing to paint application based on its new products.

Intelligent flexibility along the entire process chain

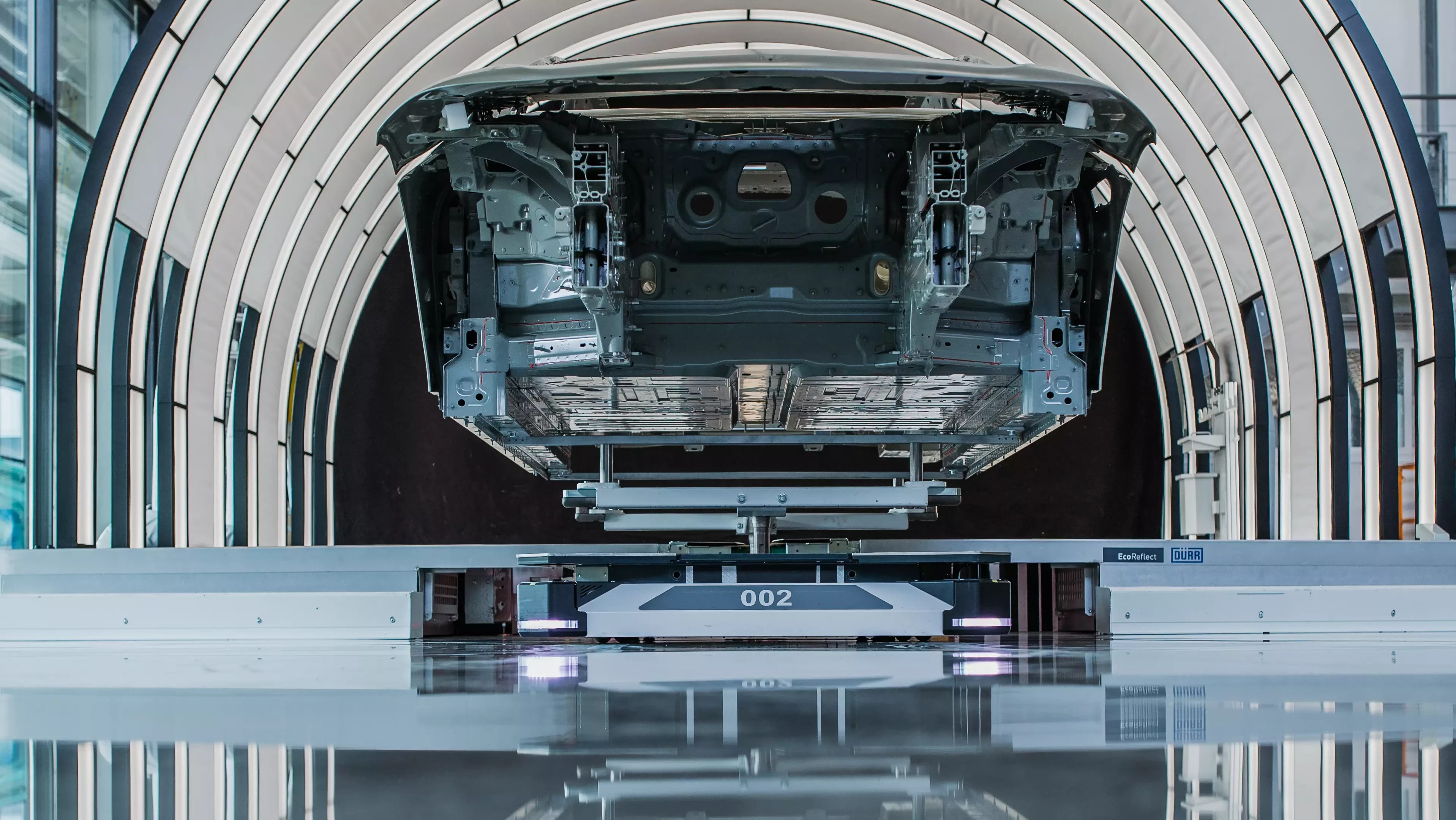

Individual stations are custom equipped using the automated guided vehicle EcoProFleet, the first AGV developed specifically for paint shops. In combination with a high-bay storage, the AGV lays the foundation for intelligent material flow control along the whole process. The DXQcontrol software controls each AGV with such a high degree of intelligence that all modules are always efficiently utilized, right from the pretreatment stage.

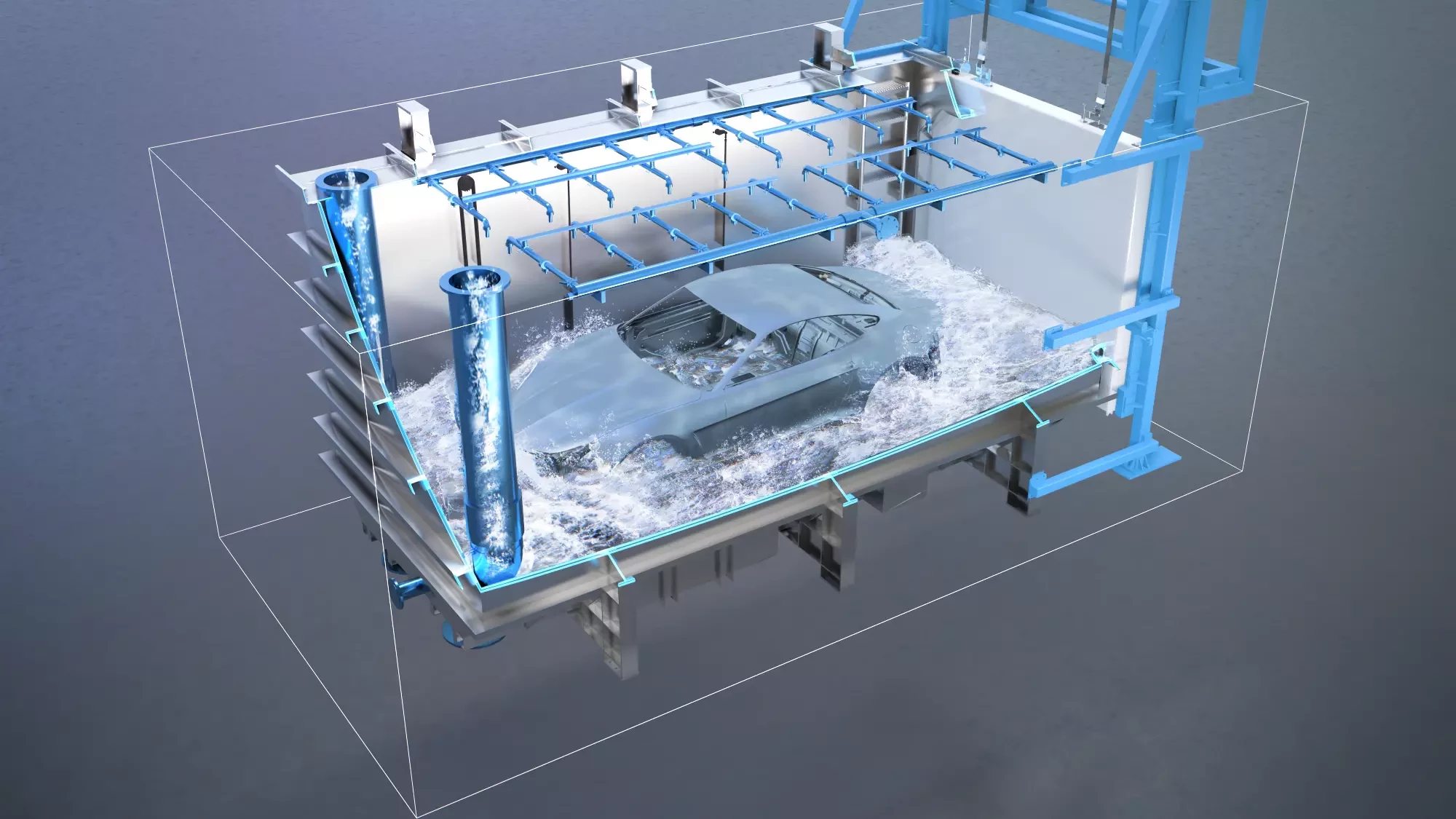

The new modular system design of EcoProWet PT is based on standardized chambers instead of immersion tanks arranged one after another. This is not only more flexible, but also saves a lot of space. Dürr has further automated the subsequent seam sealing stage with the new EcoSealJet Pro applicator and the DXQ software powered by artificial intelligence (AI). The applicator largely does away with the need for manual application, even in hard-to-reach places. This not only saves time and material, but also ensures the utmost precision and consistent quality.

For the actual painting process, the box configuration combines the application of the primer and base coat layers – the interior application and the two exterior applications – in just one spray booth. This means that two of the three usual conveying operations are eliminated in EcoProBooth. In addition, it can be used as a standard spray booth with the same robot equipment for both base coat and clear coat. It can handle everything from small cars to pick-ups.

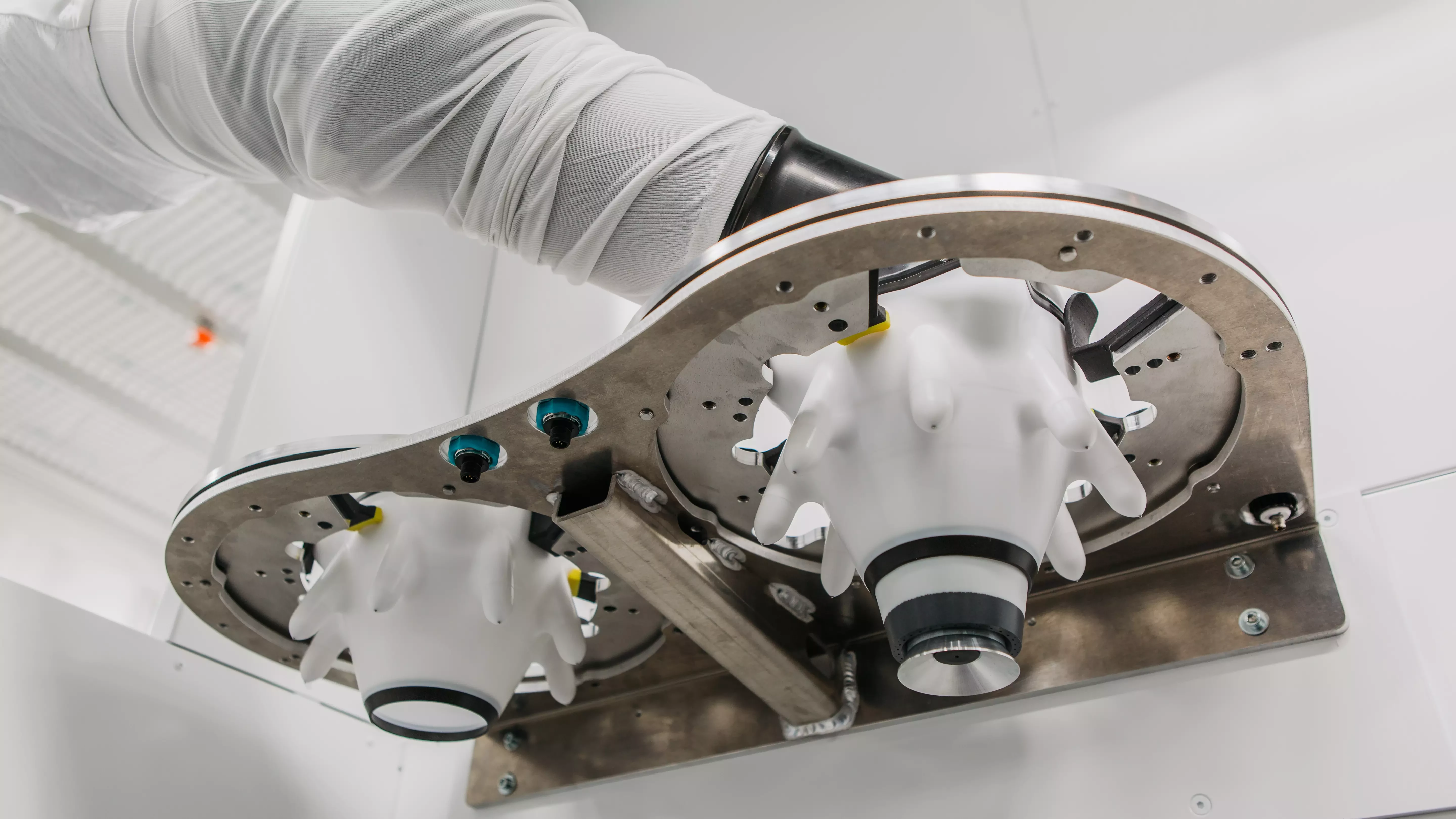

The overspray-free EcoPaintJet Pro painting system now applies even two-component paints (2C) automatically, in addition to two-tone lines for car roofs, color changes, vertical surfaces, and decorative paint applications. The latest atomizer generation, EcoBell4, delivers shorter color change times and the highest quality automated atomizer cleaning, so that more units can be painted in the same time. A major advantage is the low paint and solvent consumption, which helps to make production more sustainable by reducing VOC emissions, and the integrated RFID technology, designed to maximize the lifetime of the components and increase the first run rate.

Artificial intelligence for increased quality and availability

The software products from Dürr’s DXQ family ensure the individual processes interact smoothly in the modular concept, transforming the box-based painting system into a smart factory. A key tool in this is DXQplant.analytics, which uses AI algorithms and machine learning modules to collect and analyze sensor data, messages, and information. This helps the quality managers identify correlations early on, so that errors can be avoided and the first run rate increased. A feedback feature constantly provides the algorithm with information, so that predictions about the need for maintenance (predictive maintenance) or quality status (quality prediction) can become more and more precise.

“The many participants from all over the world, well in excess of 1,000, and all of the enthusiastic feedback are indicators of the great interest generated by the first virtual open house. Our concept for the paint shop of the future is a complete success. It delivers exactly what manufacturers need,” says Weyrauch in conclusion.