X.Cellify DC – Dry coating for electrode production

Dürr's X.Cellify DC increases efficiency and quality in battery cell production. Dry coating revolutionizes electrode manufacturing with a solvent-free and material-saving process – for up to 70 % less energy consumption and 65 % less space required in electrode coating.

With X.Cellify DC, Dürr is taking electrode coating to a new technological level. The innovative dry coating process enables resource-efficient electrode production without energy-intensive drying ovens and without the use of solvents. This reduces production space and operating costs.

Dry coating with free-standing active material film

Unlike in the conventional process, the battery material is not applied as a paste, but as a powder pressed into a stable film. This film runs through the system free-standing without a collector foil and can be completely returned to the material cycle if necessary, reducing production waste.

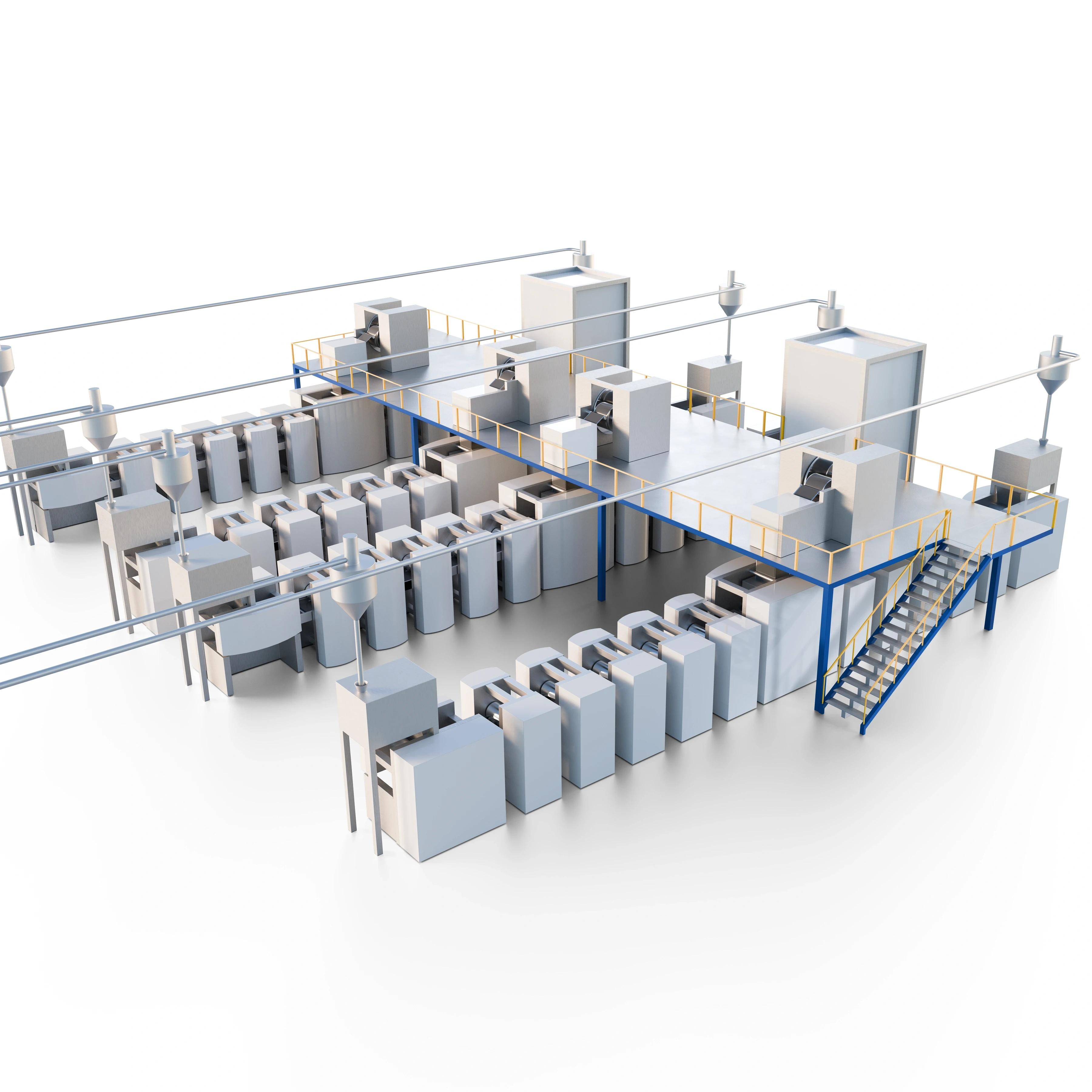

Process steps in dry coating

The production process with X.Cellify DC covers all steps of dry coating in electrode production—from precise powder dosing and film formation to final lamination onto the collector foil. In the first step, a calender forms the dry powder into a free-standing film. This film is transported further without a carrier foil, compressed to the desired layer thickness, density, and porosity through further calendering steps, and then laminated onto both sides of the collector foil. Processing without a carrier film means that the active material remains completely recyclable until lamination – a decisive advantage in minimizing waste and material loss. The subsequent lamination onto the collector foil requires only low force which prevents the deformation of the foil. This improves the processability of the electrode in the downstream process steps of battery cell production.

Sustainability and cost-effectiveness combined

Dürr's energy-efficient dry coating system represents a sustainable change in electrode manufacturing. By eliminating solvents and using a resource-saving coating process, CO₂ emissions are reduced and production waste can be drastically cut. Companies looking to make their production more efficient, sustainable, and profitable will find a forward-looking solution in Dürr's X.Cellify DC.

Advantages of X.Cellify DC

- Solvent-free electrode coating – no energy-intensive drying required

- Up to 70 % energy savings compared to wet coating

- Up to 65 % less space required in production

- Less waste due to free-standing film and complete active material recovery

- Gentle lamination in electrode coating for highest cell quality

- Suitable for lithium-ion batteries as well as all other current cell chemistries and solid-state batteries