Part.X - Separation processes

Many manufacturing processes produce volatile organic compounds (VOCs) and hazardous air pollutants (HAPs). These emissions must be properly controlled.

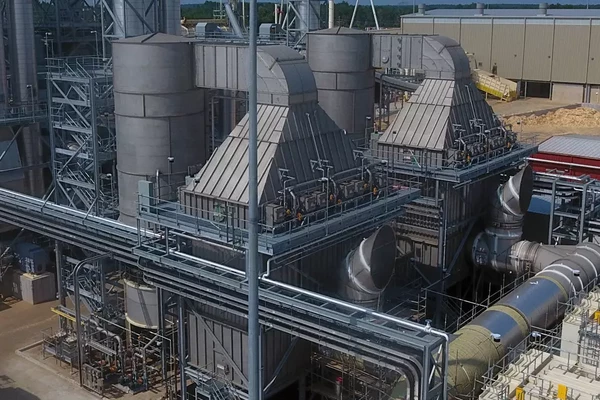

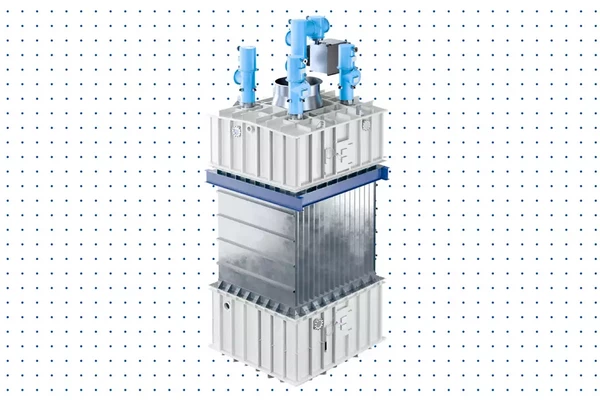

Dürr delivers environmental technologies to manage emissions of VOCs/HAPs, NOx, acid gasses, acid mists, and particulate control. A strong heritage of technical development and innovative solutions enables Dürr to provide consistently reliable and energy-saving systems for new or upgrade, simple or complex, large or small projects covering a wide spectrum of industrial applications.

A complete engineered systems approach could include wet electrostatic precipitators, wet scubbers, venturi scrubbers, distillation equipment and purification by distillation systems, as well as oxidizers to help ensure environmental compliance. Dürr delivers environmental technologies that handle VOCs, odors, acid mists, mercury, NOx, particulates, and other emissions.