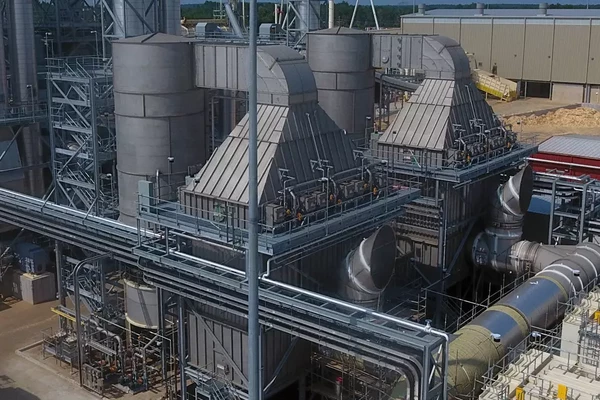

Part.X PV – Venturi scrubber

Dürr's Part.X PV offers high-efficiency particulate removal. This product was formerly known as the TurboVenturi.

Operating principle Part.X PV

The primary purpose of the Part.X PV venturi scrubber is particulate control. The principle of particulate removal is based on particles colliding with, and becoming entrapped in, liquid droplets. The smaller the dust particles, the smaller the liquid droplets required for removal. The direct relationship between gas velocity and pressure drop in the venturi throat determines the relative size of the particles that are removed. The venturi imparts momentum on the particles to be removed via acceleration in the throat, effectively making smaller particles act like larger particles.

Part.X PV benefits

- Low maintenance, high-efficiency performance

- Handles high temperature, heavy dust loading, and abrasive, sticky, and difficult particulate

- De-watering capabilities ensure virtually no liquid droplet carryover

How it works

- Gas from the process enters the venture vertically downward. Scrubbing liquid is introduced through tangential inlets at the top of the venturi, blanketing the walls as it swirls down the converging section of the throat, eliminating particulate buildup and protecting the venturi from high temperatures

- This falling film of swirling liquid increases in thickness as it converges and is atomized by the high-velocity gas stream in the venturi throat, thereby entrapping the particulate for separation from the gas in the cyclonic separator

- A flooded elbow between the venturi and the separator holds a liquid reservoir, which absorbs the impact of particulate in the high-velocity gas stream, which minimizes erosion of the metal surfaces

- A cyclonic separator centrifugally separates the particulate and liquid from the gas stream

- The liquid drains through the bottom cone to the recycle pump(s) and is circulated back to the venturi

- The cleaned gas exits from the top of the separator

Application areas Part.X PV

Every Part.X PV venturi scrubber is engineered to handle high inlet temperatures and process high particulate concentrations, where the required level of particulate removal can be attained by applying the correct pressure drop. In applications where extremely low particulate concentrations are required, the scrubber can be designed as a pre-scrubber with low pressure drop, preceding a wet electrostatic precipitator to achieve the required removal efficiency and maximize energy savings. While the Part.X PV is primarily a particulate removal device, it is versatile enough to use in a variety of applications to effectively treat difficult emissions, as well as large or fluctuating gas flows. The Part.X PV can be designed to capture SO2 and HCl from the gas stream, together with particulate.