Part.X PW – Wet Electrostatic Precipitator (WESP)

Dürr Part.X PW wet electrostatic precipitators are used to effectively clean industrial gases of fine particulate matter, acid mists and aerosols to meet environmental regulations and/or protect downstream equipment. The key features of Part.X PW systems include maximum removal efficiencies, reliable operation, and low operating costs, while significantly reducing the need for maintenance.

Dürr Part.X PW WESP Benefits

- Standardized modules significantly reduce installation time and help to optimize shipment

- Can achieve contaminant removal efficiencies of up to 99.9%

- Self-cleaning robust design reduces maintenance requirements, ideal where the process flow contains tars

- Can be combined with gas quencher, gas scrubber or thermal oxidizer, as required, for multi-pollutant emissions control

- Corrosion-resistant alloys are used when acids are present in the process flow

- Optimized emitting and collecting electrode design supports higher operating voltages and optimum corona generation, resulting in higher efficiency contaminant capture

- Improved high intensity off-line cleaning system reduces maintenance, eliminates carryover of entrained matter during washing and provides better operational performance during cleaning. Improved cleaning also means a reduction in chemical consumption.

- Improved performance provides increased protection of downstream equipment, for example in thermal oxidizers (e.g., RTOs), resulting in more efficient RTO performance and longer RTO media life

Dürr Part.X PW WESP Operating Principle

The process discharge gas to be treated is directed to a dedicated quencher or scrubber to be saturated to the adiabatic dew point and for removal of large particulate. The gas then flows into the bottom of the wet electrostatic precipitator (WESP). A gas flow distributor in the inlet plenum ensures optimum gas flow distribution across the collecting tubes. Discharge electrodes, mounted on a high voltage frame, electrically charge the incoming contaminants (solids, condensable matter, acid mists and/or aerosols) for collection on the collecting tubes. From here, the cleaned gas is discharged from the WESP system. A washing system sprays water (with chemicals, if required for specific applications) to clean the WESP interior for optimal collection efficiency.

Designs for larger gas volumes using multiple WESP modules benefit from a process gas shut-off, to operate cleaning cycles offline, thereby reducing the impact of cleaning cycles to emissions levels.

WESP systems supplied by Dürr provide a higher collection efficiency than conventional WESPs , due to optimized discharge electrode design and operation at higher energy intensities.

Part.X PW WESP Application Areas

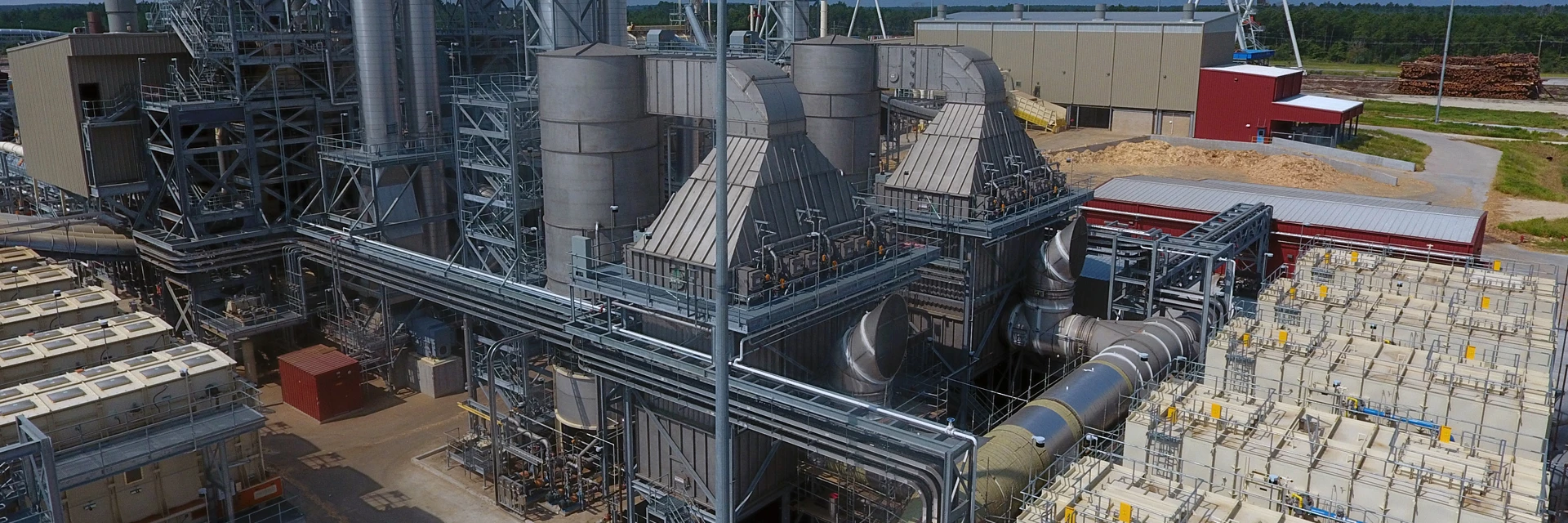

Dürr Part.X PW WESP air pollution control systems are the ideal solution for almost all sectors of industry including non-ferrous metallurgical and iron & steel, mineral processing, wood panel, pulp & paper, bioenergy, waste incineration, and petrochemical.

Applications include:

- Boilers

- Calcining

- Ceramics/catalyst

- Electrode production

- Food processing

- Foundries

- Petrochemical FCCU

- Smelters

- Sulfuric acid plants

- Waste incinerators

- Wood dryers

Part.X PW Technical Specifications

Dürr wet electrostatic precipitators are a particularly suitable and cost-effective solution for removing:

- Particulate matter (“dust”), especially fine, submicron material including heavy metal fumes

- Condensed volatile compounds, including tars

- Acid mists, including sulfuric and hydrochloric acid mists

- Aerosols, including water droplets in odorous gas streams

Dürr Part.X PWs WESPs can remove up to 98% of particulate in a single stage depending on the characteristics of the gas stream. Additional removal up to 99.9% is possible with additional modules in series. Our experienced engineers will provide the optimum particulate control solution for each unique application.