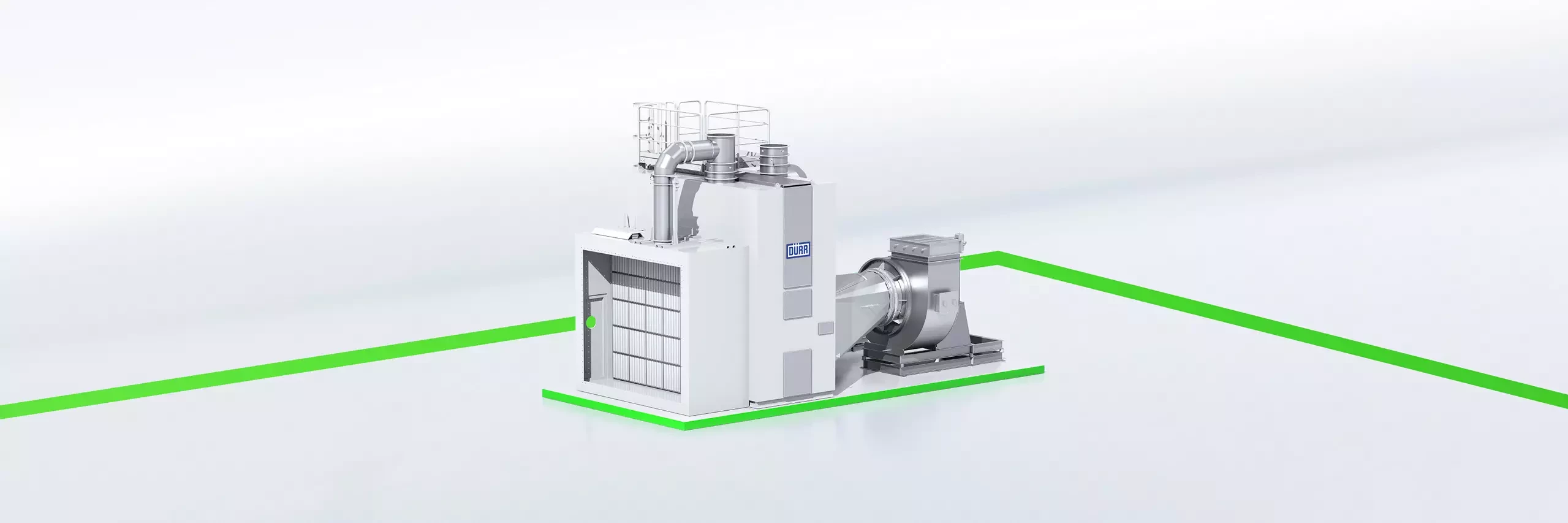

Sorpt.X – Sorptive processes

Dürr offers proven solutions for emissions control utilizing both absorption and adsorption technologies.

If the exhaust air comes into contact with a medium that the pollutant dissolves in more effectively than in the air, the pollutant moves into the medium and the clean air can be discharged from the system. The absorption and adsorption processes differ significantly in the way that they function.

Adsorption is used for concentrating the pollutants. After this, pollutants still have to be removed from the exhaust air by another system. Sorptive systems are also able to recover solvents by high efficient distillation. By contrast, absorption removes pollutants from the exhaust air. It is generally used for cleaning flue gases. The two processes are described in more detail below.

Adsorption process

The purpose of the adsorption process is to concentrate the pollutants. It is needed when the exhaust air contains a low to medium pollutant concentration. The pollutants form a physical bond with the adsorbent, with the result that they are removed from the air and concentrated in the adsorbent. The most widely used adsorbents are zeolite materials and activated carbons.

Downstream exhaust air treatment

After the pollutants have been concentrated, they can be transferred to a catalytic or thermal oxidation system, where they can be removed. The cleaned air can then leave the system. This is a more cost-effective and efficient process for purifying exhaust air with a low concentration of pollutants. Condensation and solvent recovery systems can also be used after the adsorption process, which allows the materials to be recycled if required.

Regeneration of the adsorbent

After a certain period, the adsorbent has to be regenerated to ensure that it does not become saturated with the pollutants and unable to take in any more material. This process is known as desorption and uses hot air, steam, or an inert gas.

Two different types of adsorption process are available. The first is fixed bed adsorption, which involves using several adsorbers alternately in adsorption and desorption mode. The second is adsorption with a continuously rotating rotor system, consisting of a specially designed concentration rotor.

Carbon adsorption systems Dürr offers regenerative and non-regenerative carbon adsorption systems. Solvents from process exhaust air streams can be removed, recovered and purified. These proprietary solvent recovery systems also feature high-efficient distillation equipment for solvent distillation.

Absorption process

Absorption also involves one substance taking in or dissolving another substance. The pollutant is generally a gas, while the absorbing medium is usually a liquid, but can also be a solid. Gas scrubbing is a typical application. In this process, unwanted exhaust gas pollutants or by-products of combustion, such as sulfur oxides, halogens and their acids, and chemicals such as ammonia, are removed directly from exhaust gases or exhaust air. The gas scrubbing phase generally follows the oxidation process and sometimes also precedes it. Dürr offers a variety of acid gas removal technologies including wet scrubbers, wet acid gas absorbers, spray dryer absorbers and dry sorbent injection.