Sorpt.X SB – Biogas Purification

Designed to capture more than 98.5% of the methane and purify it to pipeline quality renewable natural gas (RNG), Sorpt.X SB biogas upgrading/purification systems remove H2S, CO2, and light siloxanes from the digester gas produced at agricultural and animal waste (manure) facilities, wastewater treatment plants, and landfill sites.

Dürr Sorpt.X SB Benefits

When purified, biogas can be added to the natural gas grid and used in cogeneration applications to produce electricity, generate heat, and fuel vehicles.

Depending on the characteristics of the biogas stream, Dürr offers both water scrubbing and membrane separation solutions for biogas upgrading/purification.

Water Scrubbing

Water scrubbing systems utilize water absorption technology to process biogas from anaerobic digesters/wastewater plants and purify it to pipeline quality natural gas. The regenerative wash water system reduces water usage while achieving low methane loss.

The water scrubbing system features:

- Chemical-free operation

- High-pressure packed media bed

- Air stripper to remove CO2 and H2S, with minimal methane loss

- Regenerative wash water system to reduce water usage

- Self-regenerating desiccant dryer to dry the product gas to a dew point of -40°F

- Low methane slip of 1.5% or less

- Skid-mounted and modular design that allows for easy installation and servicing

- Flameless regenerative thermal oxidizer to treat tail gas, if required

Membrane Separation

Dürr also offers a containerized membrane separation system to minimize footprint, installation efforts and time. The modular design allows for fast start-up, immediate product gas readiness, and minimal operator attention and maintenance requirements.

Membranes are sourced from industry market leaders, resulting in more than 99% methane capture, the highest gas purity possible, and less than 0.2% methane loss. Aggressive conditioning at the membrane feed with multi-stage cooling, drying, and filtering maximizes membrane life and system reliability.

Based on site requirements, Dürr can perform an in-depth study to determine whether water scrubbing or membrane separation is the best technology for the specific application.

Fast, Simple Installation

Each system is skid-mounted and modular in design, which requires a smaller operational footprint and allows greater integration flexibility at the application site. Stainless steel wetted system components are factory assembled and tested to performance parameters.

Every skid package comes fully assembled, wired, and component tested at the factory to the extent possible prior to shipment. All equipment ships on commercial trucks. This shortens the installation timeframe and helps ensure an effective start-up. Dürr can also provide full turnkey installation and startup services, preventive maintenance, and fulfill future service/parts requirements.

Operational Reliability

An advanced electronic control system automatically optimizes the system for high gas yield. Gas analyzers provide continuous monitoring of the inlet and outlet biogas, reporting H2S, CH4, CO2, and O2 levels. The entire control system, variable frequency drives, and gas sample monitoring system are located in a climate-controlled, lighted, skid-mounted “control house” with locking access door. The operation of the system can be monitored and adjusted remotely.

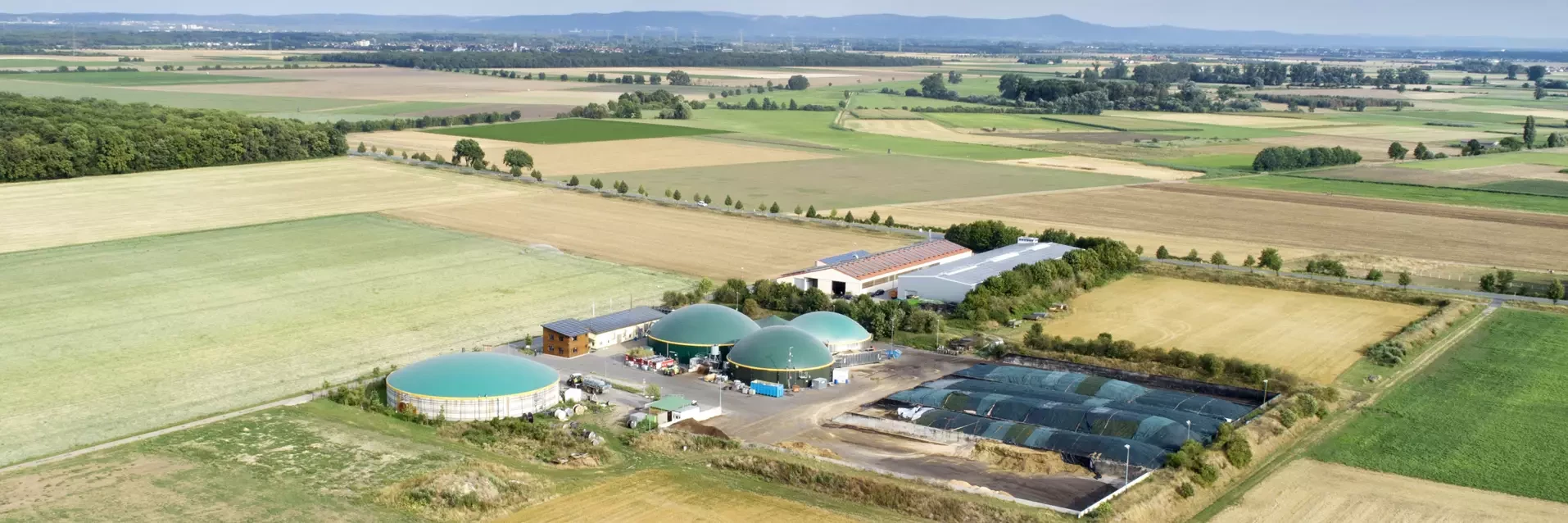

Sorpt.X SB Application Areas

Water scrubbing and membrane separation are effective methods for purifying biogas from digester, wastewater treatment, landfill or other biogas streams. The process equipment of the Sorpt.X SB biogas upgrading/purification system can be tailored to specific applications to remove particulate, H2S, CO2, H2O and siloxanes, and can capture more than 98.5 percent of the methane.

Tail Gas Treatment

Dürr offers a range of oxidizer systems to treat tail gas for all popular biogas upgrading/purification technologies, including water scrubbing, pressure swing adsorption (PSA) and membrane systems. The systems handle a wide range of methane content and in most cases, run fuel-free by utilizing the tail gas as the energy source.

H2S and Siloxane Treatment

Partnerships with world-class developers of H2S and siloxane removal systems enables Dürr to provide a complete biogas upgrading/purification system that meets its customers’ design requirements.

Our strong vendor management and service division provides substantial cost-savings to our customers while ensuring viability of the entire system.

Sorpt.X SB Biogas Purification System Technical Specifications

| Process | Water scrubbing | Membrane separation |

| Operating principle | Pressurized water absorption | Gas permeation |

| Methane capture rate | ≥ 98.5% | ≥ 98.5% |

| Methane slip | ≤ 1.5% | 0.2-1.5% |

| H2S treatsment | Chemical, media-based, iron sponge, biological | Chemical, media-based, iron sponge, biological |

| Avanced telemetry | VPN equipped | VPN equipped |