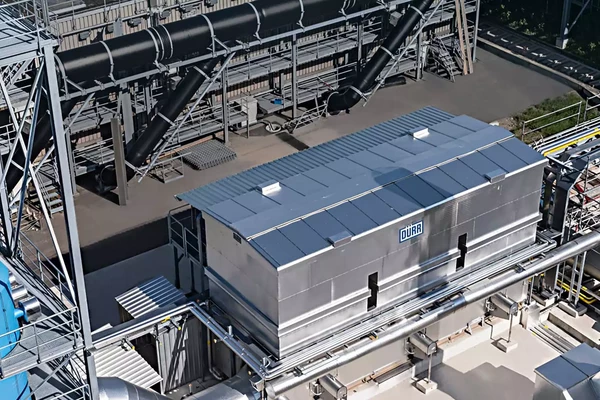

Oxi.X RV – Flameless regenerative thermal oxidizer (RTO)

The Dürr Oxi.X RV is a unique, single-bed, flameless regenerative thermal oxidizer (RTO) in a compact, modular design with low running costs for VOC abatement and controlling hazardous air pollutants (HAPs). The system combines high VOC destruction, simple design, reliability, and superior energy efficiency. Our Oxi.X RV was formerly known as Vocsidizer®.

Oxi.X RV RTO benefits

Regenerative thermal oxidizers (RTOs) with internal heat exchangers offer unparalleled efficiency and simplicity. Once the system achieves operating temperature, the thermal energy released by oxidizing solvents is often all that is needed to achieve self-sustain operation on auto therm. And because they operate at higher temperatures, they are effective for a wide range of solvents including heavy volatile organic compounds (VOCs):

- Complies with the strictest European legislation

- Negligible NOx production

- 95% to 98% nominal heat exchange efficiencies ensure almost no energy consumption

- Very low operating costs

- Design simplicity provides operation reliability

- Rugged construction and simplicity ensure long life and minimum service costs

Oxi.X RV RTO Operating principles

For VOC control, HAPs control, and odor control, the innovative, patented design of the Oxi.X RV regenerative thermal oxidizer (RTO) meets most environmental regulations with remarkable energy efficiency and design simplicity. The oxidation reactions, which purify the process exhaust, occur entirely within the heat exchange media. There is no open flame and therefore none of the unwanted by-products of flame combustion.

The Oxi.X RV offers effective VOC control with exceptional energy efficiency. Little, if any, supplementary fuel is required to sustain oxidation once initial thermal operating conditions are achieved. The Oxi.X RV also easily achieves thermal efficiencies as high as 98%. Even at very low VOC concentrations, the latent energy in the solvent is enough to sustain thorough oxidation. A natural gas injection system provides supplementary fuel if needed. The absence of a burner and a classical combustion chamber, along with its modular design, reduce capital and installation costs. The low-maintenance design also provides years of trouble-free operation.

Oxi.X RV RTO Application areas

The Oxi.X RV regenerative thermal oxidizer (RTO) is ideal for multiple source installations with low to mid solvent concentrations such as package printing, coating and odor control. An optional secondary heat recovery system for air, hot water, thermal oil or steam is an additional possibility to reduce plant energy costs.

Oxi.X RV RTO Technical specifications

- Flow capacity: 1,000 to 70,000 Nm3/h (installations are made with single, twin or multiple units)

- VOC destruction efficiency: 97.5% to 99.7%

- Thermal efficiency: 95% to 98% depending on the type of media

- Supporting energy if required: Gas or Electricity