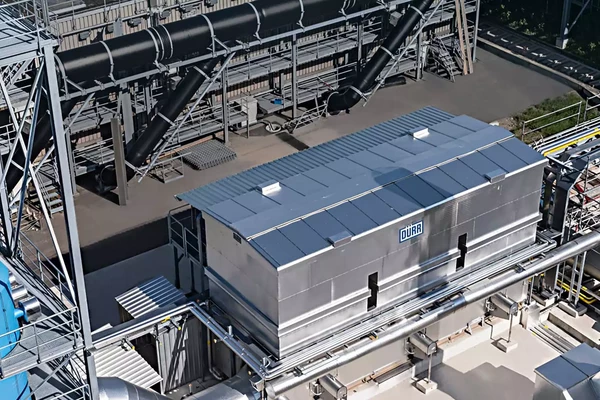

Oxi.X RC – Regenerative Thermal Oxidizer (RTO)

The Oxi.X RC regenerative thermal oxidizer (RTO) from Dürr delivers simplicity and cost-effectiveness. The two-chamber, single-vessel system delivers 99+% VOC destruction of volatile organic compounds and thermal efficiencies up to 97%. When it comes to VOC abatement, odor control, and managing hazardous air pollutants (HAPs), the Oxi.X RC RTO provides exceptional operating economy. For many applications, the Oxi.X RC RTO will run in a self-sustaining mode with no additional fuel required for VOC control, as well as odor control. This product was formerly known as the CleanSwitch® RTO.

Oxi.X RC RTO Benefits

- Proven design – over 300 installations since 2000

- VOC destruction efficiencies of 99+% to help meet stringent regulatory codes

- Thermal efficiency up to 97% provides reduced operating fuel costs

- Single valve – non-contacting, non-wearing, positive sealing via high-pressure air provides trouble-free operation, resulting in low maintenance costs

- Electric valve drive delivers quiet operation and reliable performance, even in severe climate conditions

Oxi.X RC RTO Operating principle

The Oxi.X RC RTO takes its name from the Dürr patented switch valve that keeps cleaned air totally separate from dirty process exhaust. The valve utilizes a double-air seal and is the only moving part in the unit. The simple oscillating design promotes uniform air distribution and results in a maintenance-friendly unit. The innovative design of the Oxi.X RC RTO, along with the switch valve, virtually eliminates pressure spikes, resulting in a smooth flow transition between heat recovery chambers. The design also makes the Oxi.X RC regenerative thermal oxidizer (RTO) the best solution for pressure-sensitive processes.

Simple, modular design

Designed to reduce complexity, the Oxi.X RC regenerative thermal oxidizer (RTO) provides cost-effective benefits with its flexible, modular design. Units up to 65,000 SCFM are supplied skid-mounted for fast installation time. These units are 99% factory assembled for a simple and economical installation. A climate-controlled, skid-mounted control room is included for easy access to controls in any type of weather.

Oxi.X RC RTO Application areas

The Oxi.X RC regenerative thermal oxidizer (RTO) provides simplicity and cost-effectiveness in a 2-chamber, single-vessel design. For many applications, the Oxi.X RC RTO will run in a self-sustaining mode, when no additional fuel is required to destroy volatile organic compounds (VOCs) and achieve clean air compliance. Additional features and benefits include:

- Electric valve drive delivers quiet operation and reliable performance even in severe climate conditions

- Climate-controlled, skid-mounted control room simplifies installation and provides easy access to the controls

- Smooth valve switching with negligible pressure fluctuation for better energy efficiency

- Factory pre-assembled, pre-wired and pre-tested to provide significant savings of time and money during installation and start-up

- Media chamber — positive separation of media beds without metal divider walls

- Ceramic media bake-out for easy removal of organic deposits

- Cost-effective, engineered ceramic heat exchange media beds with low-pressure drop reduces electrical operating costs

- Optional secondary heat recovery by air, hot water, thermal oil, steam, electricity generation or adsorption cooling

- Multiple fuel options include natural gas, propane, butane, fuel oil, and gaseous or liquid bio fuels

- Optional hot-side bypass system for use in high-solvent load applications

Oxi.X RC RTO Technical specifications

| Single unit, low capacity | 20,000 to 90,000 SCFM | ||

| VOC destruction efficiency | 99+% | ||

| Thermal efficiency | 95% to 97% | ||

| Autothermal operation | 3-4% LEL |