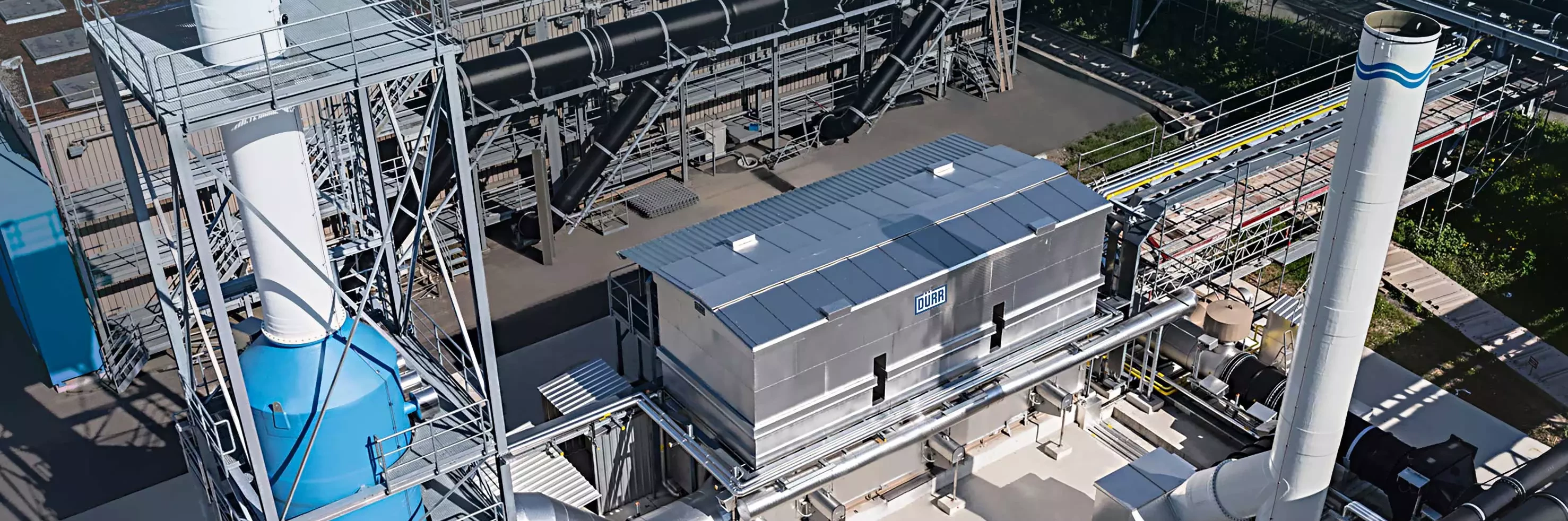

Oxi.X RE – Regenerative thermal oxidizer

Regenerative thermal oxidation (RTO) is used in a variety of industry sectors to purify exhaust air containing solvents and odors. Highly efficient regenerative thermal processes contribute significantly toward environmental protection. The Oxi.X RE RTO systems are designed for low and medium pollutant concentrations. Their key features include an excellent thermal efficiency of up to 97%, low-maintenance design and low operating expenditure.

Oxi.X RE Benefits

- Outstanding removal efficiency ensures very low emissions

- Maximum heat recovery

- Robust, self-cleaning system

- Flexible design

Oxi.X RE Operating principle

During regenerative thermal oxidation, the exhaust air contaminated with pollutants is fed through a regenerative heat exchanger. This warms up the exhaust air, which is then very close to the reaction temperature when it leaves the exchanger. The combustion chamber converts all the pollutants into harmless substances by exposing them to a sufficiently high temperature.

The now purified gases are fed through a heat exchanger again where they lose their heat, completing the regenerative circuit. The purified, cooled exhaust air is then released from the system.

Dürr’s Oxi.X RE RTO system requires little maintenance thanks to its seal-free, horizontally arranged poppet valves. The distribution of the flow of the exhaust gases is perfectly coordinated to ensure optimal heat exchanger efficiency, thus greatly increasing the overall system efficiency.

The Oxi.X RE is available in different materials, such as mild steel, various stainless steels and Hastelloy. When installing the system, it is possible to incorporate additional external insulation to prevent corrosion and extend life span.

The Oxi.X RE is distinctive for its great flexibility and is the optimal solution for a wide range of applications. The system is also extremely versatile because upstream and downstream scrubbers, nitrogen oxide reduction systems, liquid injections and heat exchangers can be installed in a huge variety of different combinations.

Oxi.X RE application areas

The Oxi.X RE is based on a process that is suitable for all types of pollutant concentration, from very low to very high. The Oxi.X RE is particularly suited to the following applications:

- The production of chemicals such as synthetic rubber, pesticides, LDPE and PTA

- Carbon fiber production

- The pharmaceutical industry

- Roasting processes in the food industry

Oxi.X RE Technical specifications

Dürr’s Oxi.X RE RTO air pollution control system can purify air flow rates from 5,000 to 350,000 Nm3/h. It is possible to purify even greater exhaust air flow rates by using multiple units in parallel.

Depending on the solvent, the input concentration can be up to 10 g/Nm3. If a particular application produces greater concentrations, fresh air or recirculation gas can be added.

The overall thermal efficiency is normally around 97%.