Oxi.X - Burner systems

Alongside complete Air Pollution Control Systems, Dürr also provides additional parts for upgrading existing systems. These may have been originally supplied by Dürr or by other manufacturers. Because the Oxi.X burner system is used for the combustion of pollutants, it falls into the category of thermal processes for Air Pollution Control.

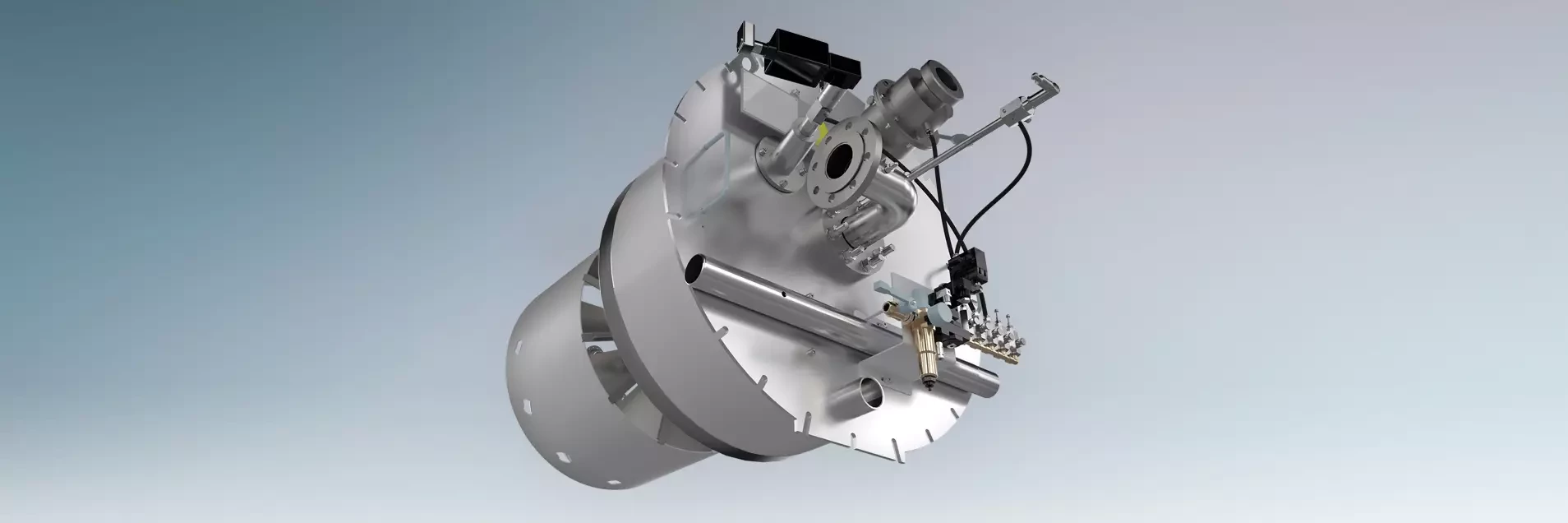

High efficient Burner Technology

One important factor in Air Pollution Control Systems based on thermal processes is the design and operating principle of the burner. Because exhaust air can contain a variety of pollutants and because burners with differing operating modes are needed, Dürr supplies a range of different Oxi.X burner systems. Each of these burner systems has different properties and functions that make it unique. Alongside the Oxi.X TR.Com burner that is described here in more detail, other Oxi.X burner systems are also available. Dürr's aim in offering different variants is to cover all possible requirements and to supply its customers with the ideal addition to their thermal oxidizer systems.

The most recent Oxi.X burners from Dürr are market leaders. They use hollow-cylinder flame technology to produce cleaner gas at lower combustion chamber temperatures than conventional burners. The gas nozzle which has been specially designed for use in the Oxi.X TR Air Pollution Control systems ensures that the combustion gas and process air are thoroughly mixed. The Oxi.X TR.Com burner is available as a gas burner, as a combination burner for two types of gas, and as a gas-oil combination burner.

It allows for significant energy savings. Depending on the application, the special shape of the flame gives perfect results at a combustion chamber temperature up to 40 °C lower than conventional cone burners. This reduces wear and extends the life span of the system

Oxi.X TR.Com benefits

- A reduction of up to 40°C in the combustion chamber temperature depending on operating parameters

- Further advanced emission reduction of formaldehyde, VOC, NOx and CO

- Exchangeable with almost all burner models

- Savings in cooling air consumption through new view glass design up to 60%

Find more information about the Oxi.X TR.Com burner in our service area.