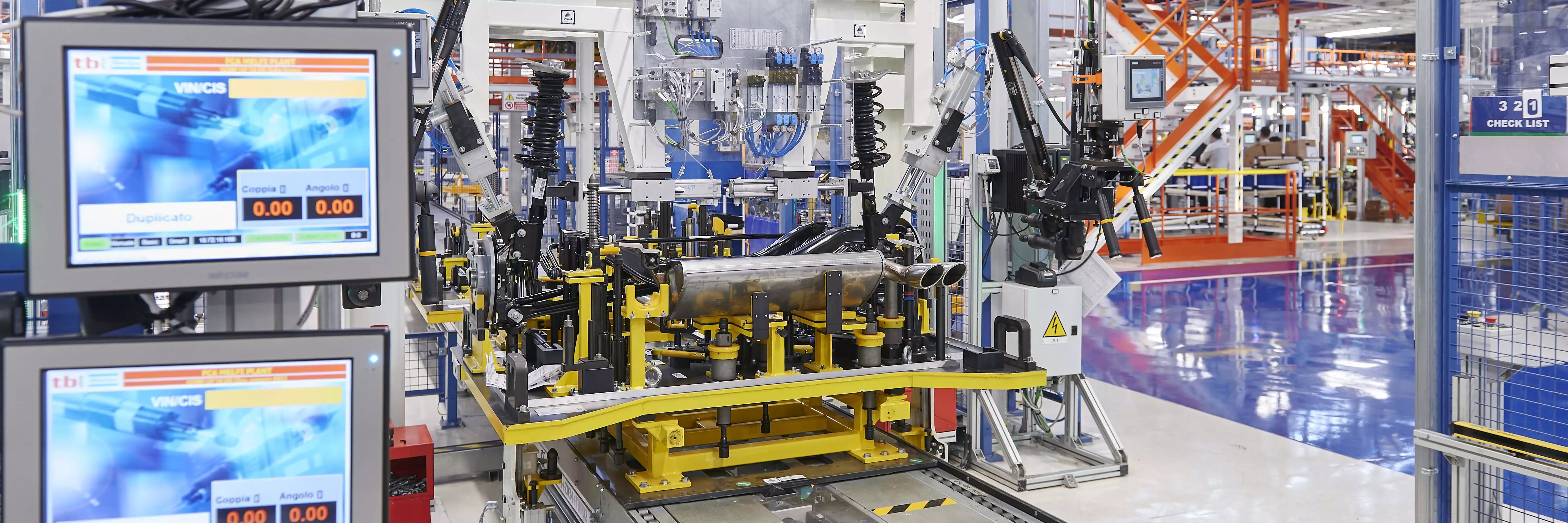

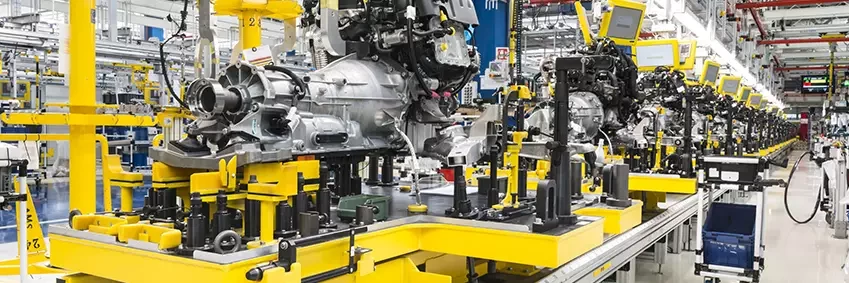

Subassembly line

The indispensable element for a complete turnkey system in a final assembly shop.

In a final assembly shop the subassembly lines are responsible for the main line feeding.They are located next to the main line and transport the pallets on which the mechanical parts of the car are prepared to get ready and assembled with the car body when they both arrive at the so-called marriage station.

The Dürr subsidiary CPM designs mechanical subassembly lines for front and rear mechanical parts, corner preparation, dress-up, front and rear axles, powertrain engine and gearbox preparation, front and rear suspension, and for the battery.

A pick-up station is always integrated into the subassembly lines. It puts the pallets loaded with the mechanical parts on the main line and removes the empty ones.

The subassembly lines can be part of a final assembly turnkey project, integrated into a concept with Flex decking or with any assembly line.