ProFleet - Automated guided vehicles for all applications

Dürr supplies high-performance automated guided vehicles (AGVs) for almost any application. Our standard systems can be individually configured to provide you with first-class, robust solutions for sustainable and efficient production at your site.

Automated guided vehicles are driverless transport systems that can move vehicle bodies, materials and other types of goods with ease. With their 360° maneuverability, Dürr AGVs replace fixed conveyor technology, making the production process particularly flexible and precise. All ProFleet vehicles can be precisely tailored to each workpiece and, with optimized travel times and smart control, they offer individual solutions for individual requirements, regardless of workload or process. Even a wide range of payloads is possible. We can transport anything that weighs between 500 kg and 32 metric tons.

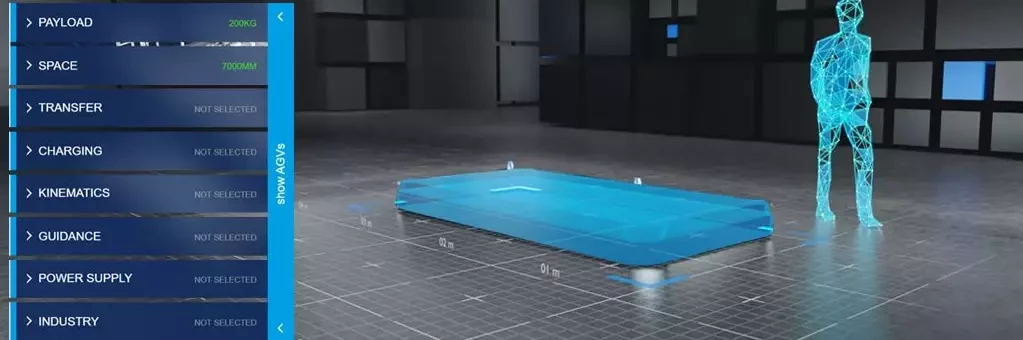

The AGV product family comes in different sizes and models and offers solutions that fulfill a wide variety of customer requirements. This applies not only to the automotive industry, but also to pharmaceutical products, textiles, paper, food and drink, and domestic appliances. ProFleet vehicles come in different standard models that can be individually customized to meet customer needs. Use our AGV configurator to find the right configuration for your application.

Our unique selling points

A global service network

With its global network and broad-based, partnership approach, Dürr guarantees that it can meet local requirements. Our engineering process is designed to accommodate the specific needs of our customers and our local service units ensure that we can always be reached.

Simple maintenance

Dürr AGVs are easy to maintain. The main components can be accessed via removable or hinged covers. The ProFleet design allows maintenance tasks to be carried out from above, without the need to tip or lift the AGV. This significantly reduces the overall time needed for maintenance.

Integration

Our AGV fleet can be integrated into a variety of different processes in a line (stations, tools, other equipment). If required, Dürr ProFleet AGVs can share operating areas with other users (for example, tugger trains and forklifts) and their open interface guarantees that your production process will run smoothly and be fully synchronized. They can also communicate with our customers’ stationary equipment and control systems.

Individual products

Dürr has a broad portfolio of ProFleet vehicles that is under continuous development. As a result, our AGVs are versatile and can be used in a variety of industries. They can also be customized to provide the best solution for your needs.

Customer benefits

- Flexible and scalable: The number of AGVs needed to ensure the required throughput and adjusted routes to meet demand and accommodate new processes

- Increased efficiency in the production chain: Direct routes between start and end points reduce the throughput time in your production process

- Easy accessibility: No safety fences needed thanks to self-locking vehicles that guarantee a high level of safety in the production environment

AGVs – Dürr is the ideal partner

The Dürr Group is one of the world’s leading mechanical and plant engineering firms with outstanding automation and digitalization expertise. We embody ongoing innovation with a focus on quality and excellent service. Since 2017, we have been manufacturing self-driving transport systems for paint shops and final assembly plants. Qualified specialists at our Excellence Center in Turin are responsible for developing the innovative ProFleet AGVs. In a total production area of 10,000 square meters, around 2,500 are devoted to the ongoing development of AGVs.