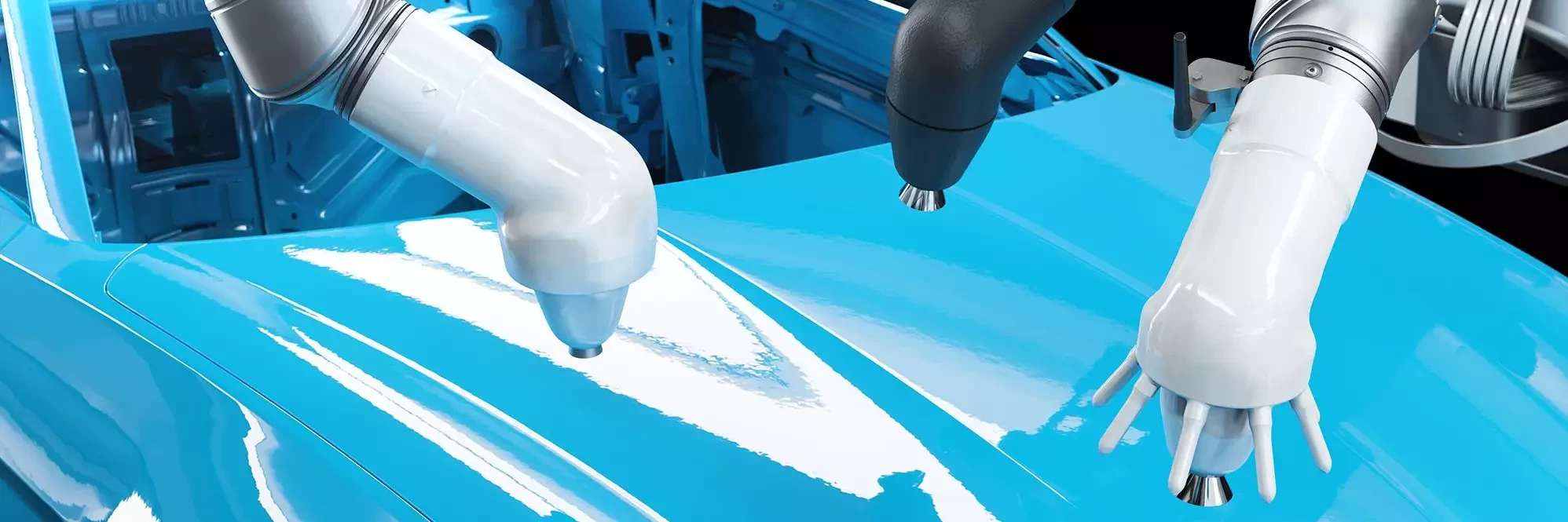

EcoBell – Rotary atomizer

Highest coating quality. Minimal paint consumption. Shortest color change times.

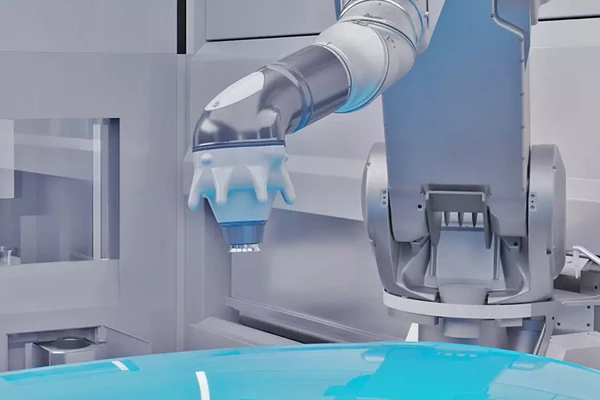

Since 1998, Dürr has repeatedly redefined the standard in the market with the EcoBell atomizer series. The technologies and functions incorporated were often world firsts. Even in the first generation, the mixer for 1K and 2K was integrated in the atomizer. It also became possible to paint the interior using high-rotation atomizers without high voltage, and with compact external charging, the atomizer can easily reach even hard-to-access areas in the car body.

The 2-main-needle-technology in the EcoBell3 and the 4-main-needle-technology in the EcoBell4 enable the shortest color change times and the RFID technology helps to significantly reduce the consumption of resources and the operating costs.