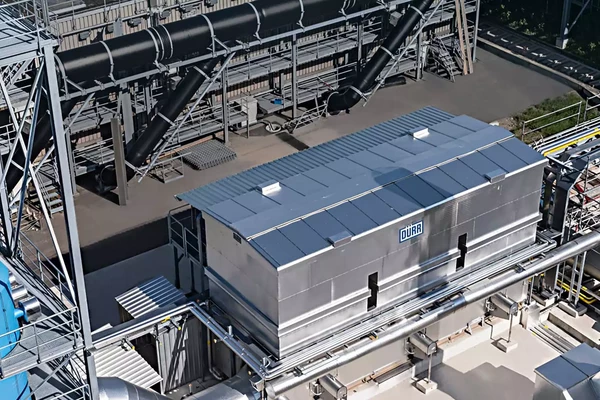

Oxi.X – Regenerative Thermal Oxidizers

Oxi.X Air Pollution Control Systems are based on a highly efficient thermal process, which is used to purify exhaust air containing solvents and unpleasant odors. They can achieve a purification level of over 99.8%. The key features of Oxi.X – Regenerative Thermal Oxidizers are their high thermal efficiency, low-maintenance design, and low operating expenditure.