Oxi.X – Thermal processes

Dürr has a comprehensive range of systems that use thermal processes for Air pollution control and is specially designed to meet customers' requirements. The thermal processes are based on the separation principle and use combustion to remove pollutants from exhaust air. In all cases in which pollutants cannot be collected for potential re-use respectively recovered, these VOCs have to be destroyed. This involves converting the pollutants in exhaust air into non-hazardous substances at specific temperatures, which allows the air to be purified.

Thermal processes – Operating principle

The only condition for the use of thermal oxidation is that the pollutants must be flammable. The pollutants in the process exhaust air can be in the form of mist, steam, or gas.

A mixture of air and one or more flammable pollutants is converted using a supply of energy. The exhaust air is heated to such a high temperature during the combustion process that the hydrocarbons it contains combine with oxygen to produce steam and carbon dioxide.

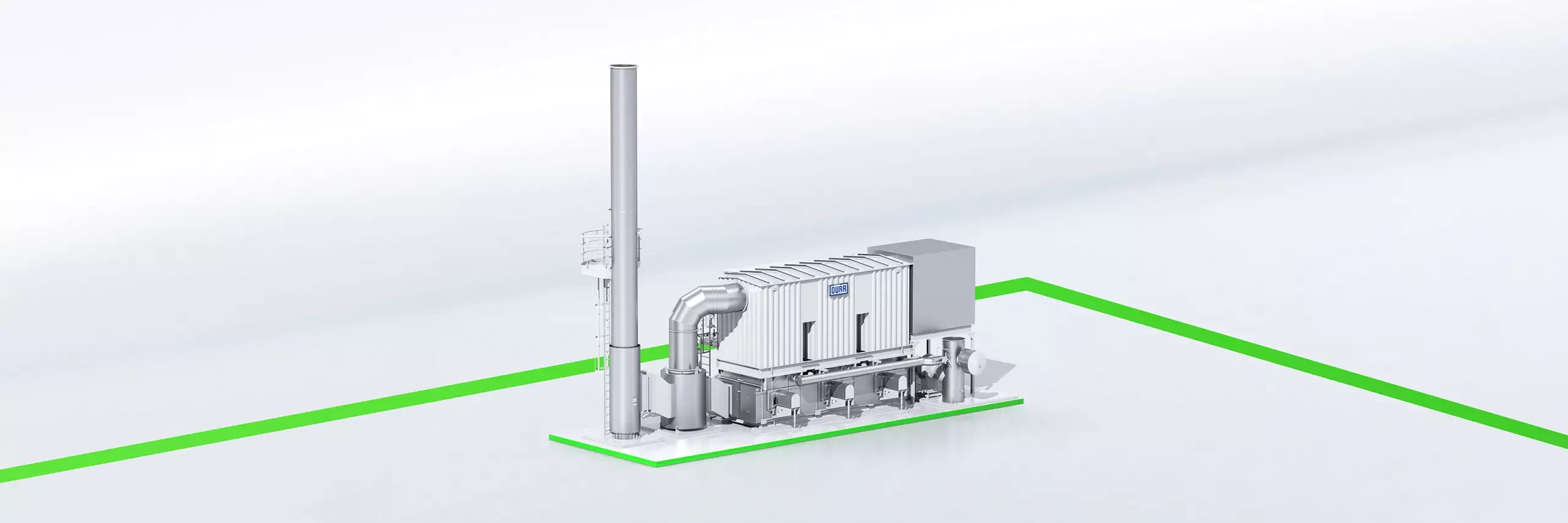

Many of our customers use this type of Air Pollution Control System because the different variants available make it suitable for a wide variety of applications. Dürr’s thermal oxidizers are designed for low to high volume of airflow and deliver high thermal and destruction efficiencies for VOC abatement. The range in construction includes special compact designs and systems that can operate in autothermal mode, so that no external energy supply is needed to purify the exhaust air. Systems that use thermal processes to incinerate pollutants are found in almost all areas of industry.

Thermal processes – Different system variants

These systems fall into two basic groups: either recuperative or regenerative, depending on the pre-heating method used.

- Oxi.X TR – Recuperative Thermal Oxidizer

Recuperative thermal Air Pollution Control Systems (Oxi.X TR) are particularly suitable where there are high concentrations of organic pollutants in the exhaust air. The only disadvantage of this type of system is the relatively high consumption of primary energy, in particular where pollutant levels in the exhaust air volume flow are low. For this reason, operators of Oxi.X TR systems always rely on downstream energy recovery units to make their systems more cost-effective. - Oxi.X DF – Direct-fired Oxidizer

The Oxi.X DF direct-fired thermal oxidizer is a special variant which is ideal for the combustion of critical substances, such as explosive, toxic, and carcinogenic pollutants. - Oxi.X Regenerative Thermal Oxidizers

The Oxi.X regenerative thermal oxidation systems (RTO) are not affected by this problem. In the regenerative method, the combustion energy pre-heats the incoming exhaust air. This allows the system to operate in autothermal mode with no external energy being used for the burner. - Oxi.X burner technology

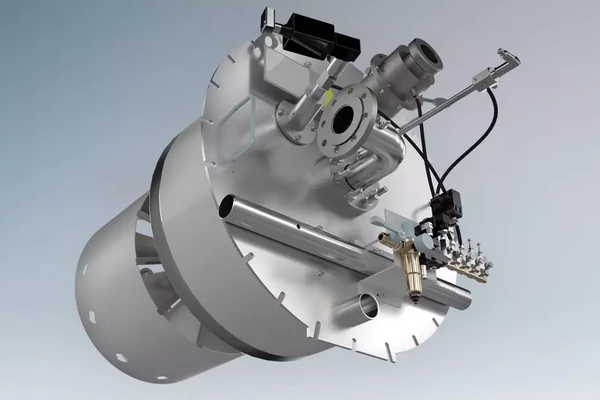

As well as complete plants, Dürr supplies additional equipment that can be retrofitted to existing systems. The Oxi.X burner technology makes the ideal addition to an Air Pollution Control System.