Somac® Line filling – Reliable. Efficient. Unique.

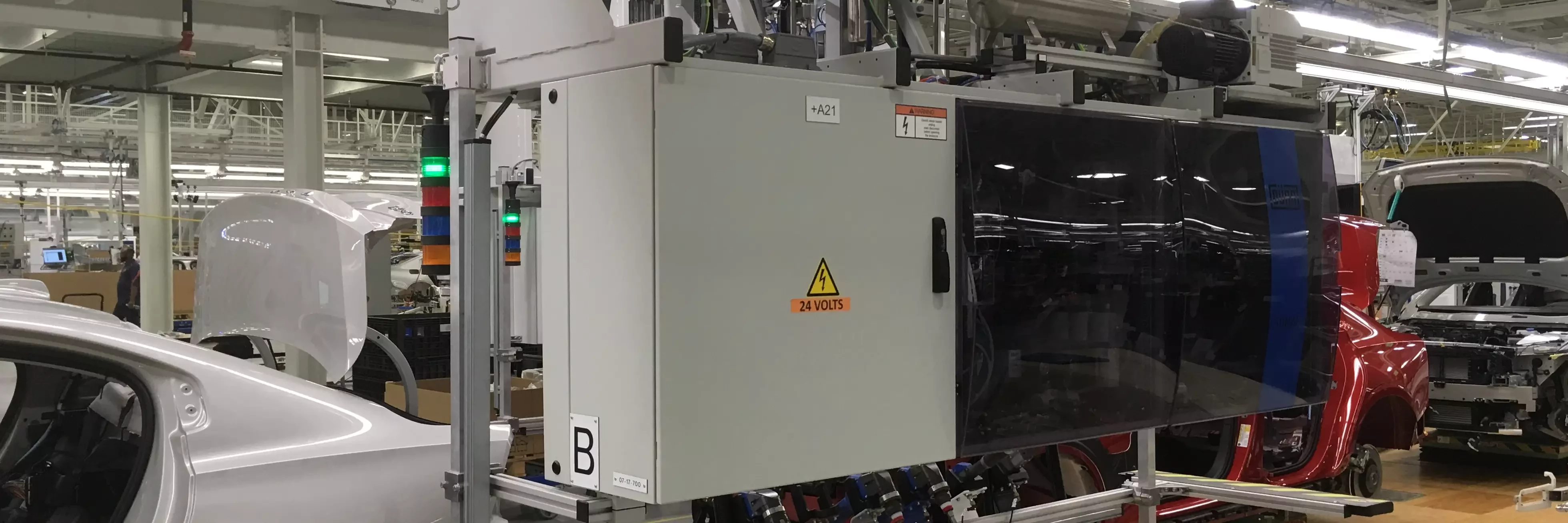

Line filling stations made by Dürr keep up with your assembly line speed and your effenciency objectives.

Benefit from our success to reduce your cost- with Dürr line filling stations you buy time optimised automatic filling processes that will be adjusted to your fluid systems. We find the best fluid combination and line-balancing for efficient filling processes in your assembly line.

Our drip free pneumatically clamping filling adapters with integrated valves are ergonomically balanced for an one-hand operation and they offer a high flow rate despite their low weight.

The color coded adapter supports are optimised for a fast and easy handling. Even if your model mix requires a higher number of fill adapters, the operator will still be ahead.

Expect a high uptime thanks to components that did prove their reliability over years. We use stainless steel for tanks, piping and drip pan (on request with WHG approval). Fittings allow easy exchange of components, nothing is welded.

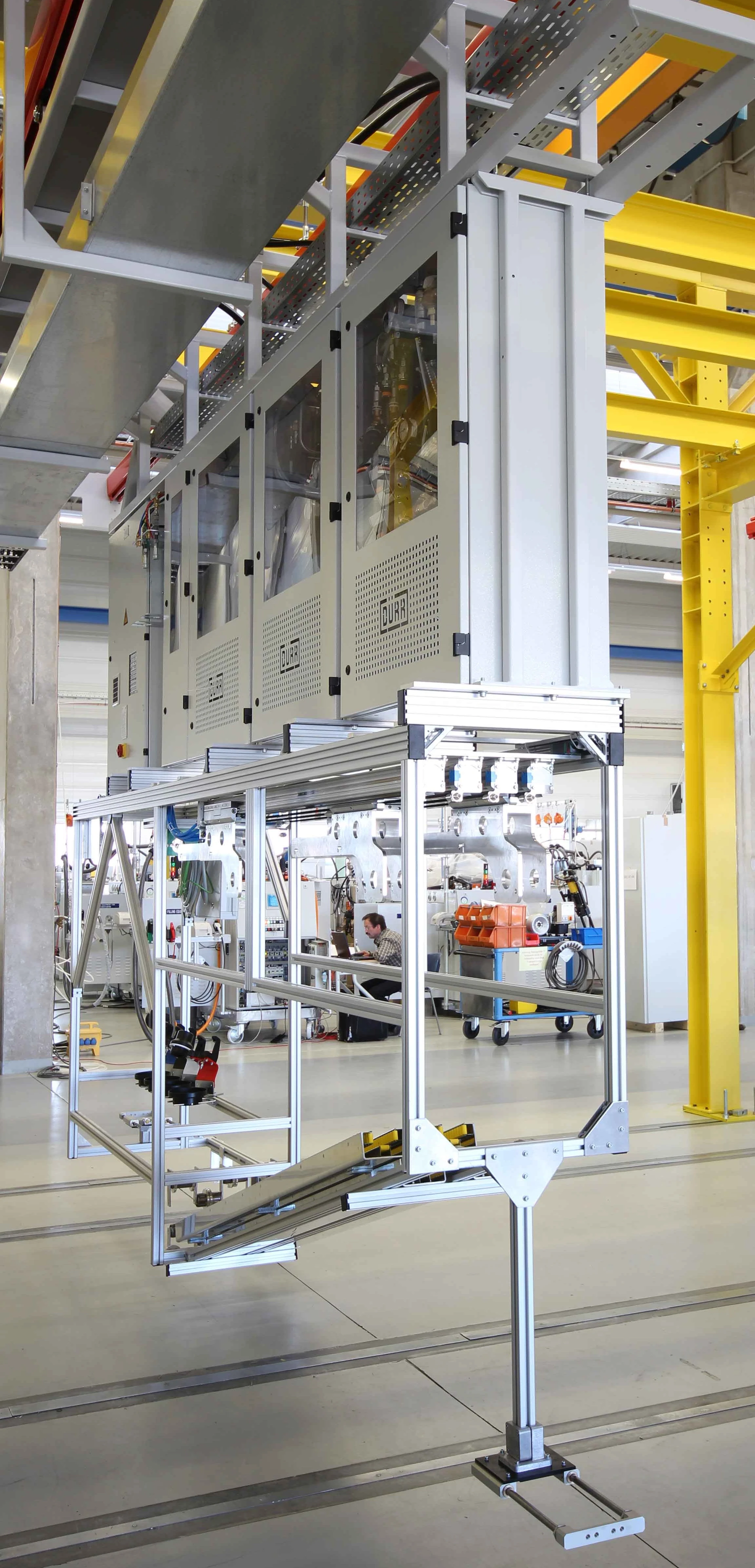

ProLine – Systematic modularity

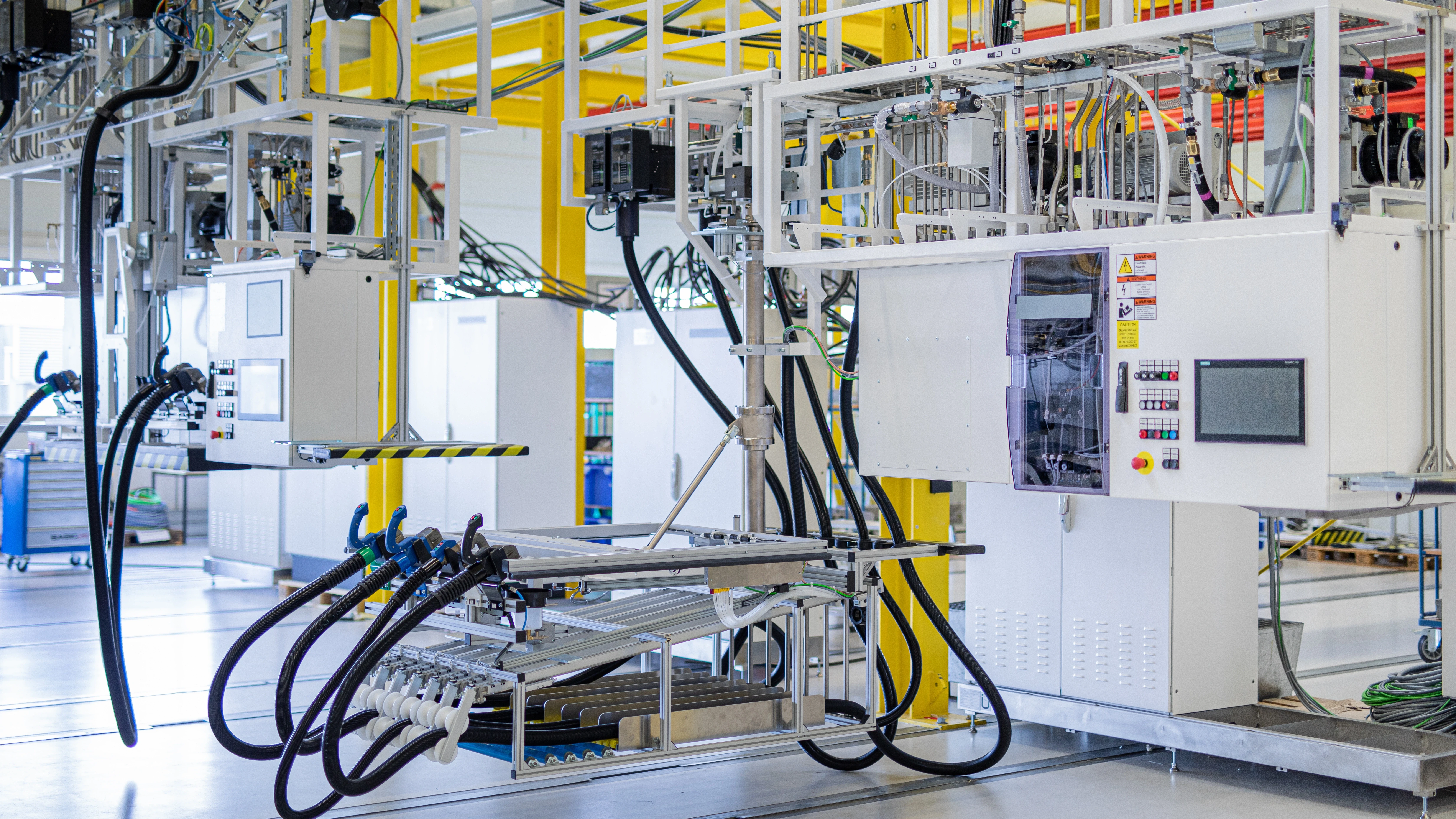

ProLine filling stations optimize the space requirements at your assembly line. The synchronously moving console of the ProLine filling stations with operator panel at eye level contains only components that need to be close to the vehicle to achieve best performance. The operator always has an overview about the filling processes and his work station. Components, which do not have to be close to the vehicle, are installed in a modular cabinet system requiring a minimum line space but providing good accessibility. All electrical connections are plugged for quick installation and easy extension. Concerning the refrigerants R744 (CO2), R1234yf and R134a, our portfolio contains A/C-modules and filling adapter.

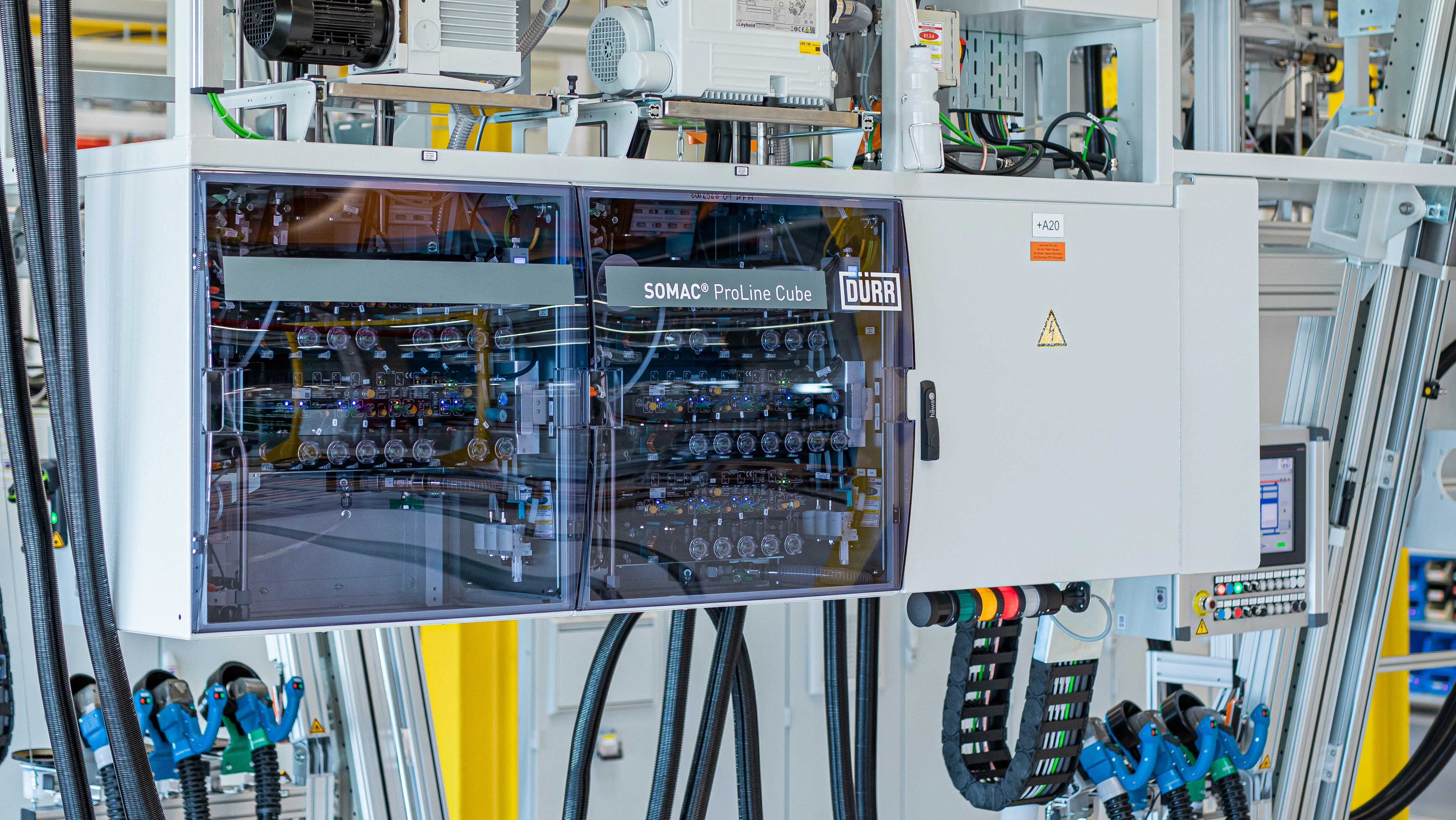

ProLine Cube Filling Station - Next Level Filling Equipment

The Somac® ProLine Cube is the new generation of filling equipment for vehicle systems on your assembly line. Featuring a modular design, the Somac® ProLine Cube ensures an optimum flow of media and reduces process times by up to 15%. Other features of the compact system include the integration of filling functions in a block design and fewer pipes and fittings. One base unit can be used for up to 4 consoles, ensuring a flexible layout across greater distances. The Somac® ProLine Cube increases the overall equipment effectiveness (OEE) of the filling equipment as well as individual media and media combinations as a result of easier maintenance and optimized availability and process quality. You can improve availability even further courtesy of optional features such as valve position monitoring, automatic draining, tool-free adapter replacement and input filter monitoring. An environment sensor enables automatic optimization of filling processes in response to ambient temperature and humidity.

Your benefits

- Up to 15% faster

- Optimized process quality and service life

- Easier maintenance

- Ergonomic G4 Blue Adapter

Functions

- Visualization of functional status using LEDs

- Cluster calibration of sensors

- Smart station operation, analysis and control

CompLine – Compact filling station for fast assembly lines

CompLine is our interpretation of a compact filling station for fast assembly lines. It consists of all required components for an efficient and clean filling in one filling console. It is divided in fluid modules without further electrical control cabinets next to the assembly line.