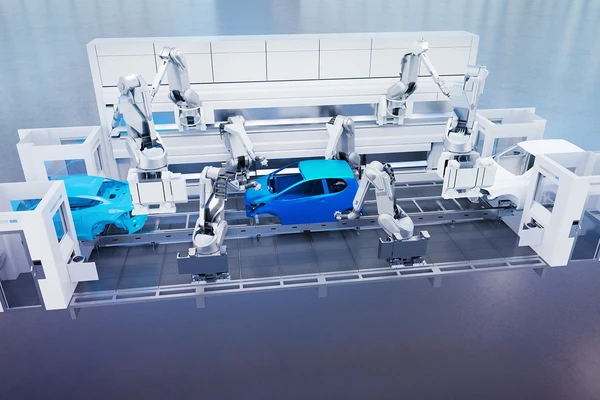

Paint robots – Modular design, capacity to spare

The third generation of Dürr painting robots is modular in nature. The design has been systematically incorporated in the 6 and 7-axis kinematic system.

These versions therefore differ only due to the additional rotating axis in the main arm. The otherwise thoroughly identical components simplify spare parts management and maintenance work and save on storage costs.

Quick-release fasteners facilitate the removal of cladding and allow extremely effective access for replacing the integrated pneumatic, control and high-voltage components. The color changer and dosing pump are mounted on the robot’s front arm, enabling rapid color changes with little paint loss and low purging-agent consumption.

EcoRP E043i – More flexibility with 7-axis kinematic system

The EcoRP E043i from Dürr’s third generation of robots has an impressive array of innovative features. Its 7th axis, which is directly integrated in the painting robot’s kinematic system, improves its maneuverability and expands its work area. This enables the robot to easily reach parts of the body that are normally hard to access. The superior maneuverability of this 7-axis robot dispenses with the need for a displacement rail in many applications. Consequently, the spray booth can be smaller, and the customer saves on rail investment and maintenance costs.

6-axis painting robot ─ Flexible for all applications

Top or bottom, obliquely suspended or standing, stationary or driven: 6-axis painting robots from Dürr can be fitted to a top or bottom-mounted EcoRail X (EcoRP E/L133i), or installed in the spray booth as a stationary model without rail (EcoRP E/L033i). Thanks to their modular design, these models with 6-axis kinematic system are used both for painting and for opening hoods. What’s more, the robot is suitable for jobs such as flame treatment, underbody sealing, and measuring coat thickness.

Scara electric strike – Your perfect painting assistant

The Scara EcoRP L030i/130i robot acts as an electric strike with a long vertical stroke. Its compact, flow-optimized design predestines the Scara robot for installation in painting booths. The Scara electric strike is installed on a compact internal rail (EcoRail S) at various heights either as the standard model (EcoRP L030i) or a traveling version (EcoRP L130i). The recently developed EcoTool Cleaner is a world first. The opening tool is inserted in the cleaner by a pneumatic pivot axis.

Swingarm robot - Enormous reach for painting commercial vehicles

Both interior painting of the loading area and exterior painting of the rear doors - The swing-arm robots EcoRP S053i and EcoRP S153i are specially designed for painting commercial vehicles. With its highly mobile swing arm the robot dives effortlessly into loading areas and thus also easily reaches areas in the interior that are difficult to access. The robot arm with its extremely stable mechanical design extends up to five meters into the bodies and folds itself back into the tightest of spaces after it is finished painting to make space for the next body. The fully automatic station offer the best accessibility for small and large vehicle bodies in a production line and is suitable for stop-and-go operation as well as line tracking.