Paint shops and application technology from a single source

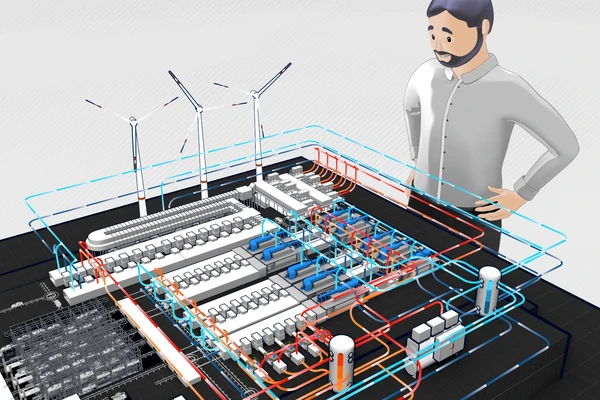

From its varied and innovative product portfolio, Dürr supplies flexible, sustainable painting solutions for all types of vehicles and transport solutions worldwide. Decades of experience and in-depth process knowledge ensure that the process of planning and implementing new plants and modernizing existing factories runs smoothly. Plants and equipment from Dürr also produce the highest quality results when painting components such as plastic parts and wheel rims.

Dürr takes into consideration customers’ specific requirements and global trends to make production plants more efficient and sustainable on an ongoing basis. With a combination of innovative ability, process knowledge and digital expertise, we develop solutions for the challenges of the future. These include new processes especially designed for painting electric cars, intelligent software solutions that increase overall equipment effectiveness and scalable layouts for a requirement-based initial investment and subsequent expansion.