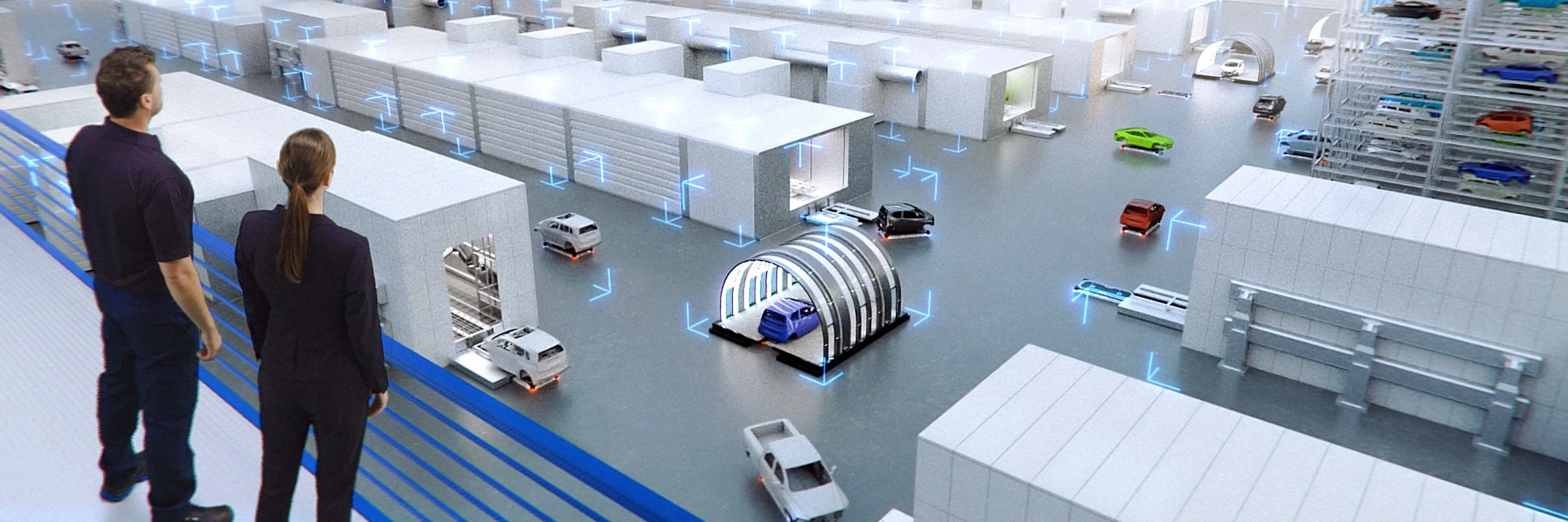

The paint shop of the future

Dürr is the world leader in automotive paint shop planning and implementation, both for the modernization of existing plants and the construction of new production lines.

Our decades of experience, in-depth process knowledge and extensive digital expertise guarantee that we take an integrated approach to the implementation of paint shops. At the same time, by combining these competencies, we will be able to overcome the challenges involved in automotive production in the future.

Dürr’s concept of the paint shop of the future allows for the highest levels of flexibility

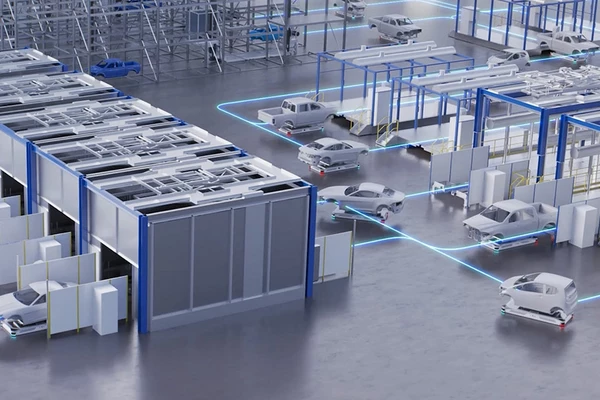

The paint shop of the future breaks away from the traditional layout used in the automotive industry and introduces a modular concept. The body parts are now painted in boxes rather than on a production line. These boxes are scalable and this makes them ideal for a wide variety of component sizes and applications. Instead of fixed cycle times, there are requirement-based process times. New models can easily be integrated at any time, which increases the overall availability of the plant. In combination with intelligent IIoT solutions, the paint shop of the future can be adapted to any production scenario.

Five pillars form the foundations for the paint shop of the future:

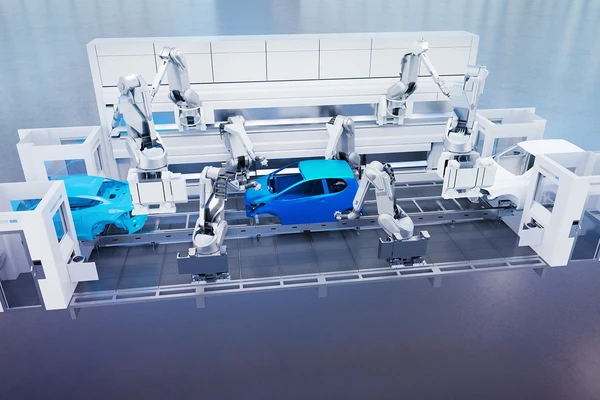

- Efficiency: Full automation, intelligent software and reduced capital and operating expenditure for the greatest possible overall equipment effectiveness

- Innovation: The latest technologies for pioneering developments

- Flexibility: Adaptable concepts for all applications, production capacities and challenges

- Sustainability: Products and processes with an environmentally friendly design for resource-efficient production

- Quality and service: Global service and support throughout the entire life cycle of the paint shop for outstanding customer satisfaction

Digitalization plays a supporting role in all five pillars. With our DXQ software products, we combine software competency and production process expertise to produce optimal solutions. As a result, digital products become enablers and drivers for all five pillars of the paint shop of the future.

Our automotive painting portfolio

- Customized new and existing plants

- Comprehensive process expertise and high-quality technologies:

- CFD simulation and planning

- Pretreatment and corrosion prevention

- Spray booths and robot application systems

- Oven systems

- Conveyor systems

- Customized software solutions for plant operation, analysis and control

- Air pollution control

- Professional implementation and start-up management

- Spare parts service, inspection and maintenance

- Service locations worldwide