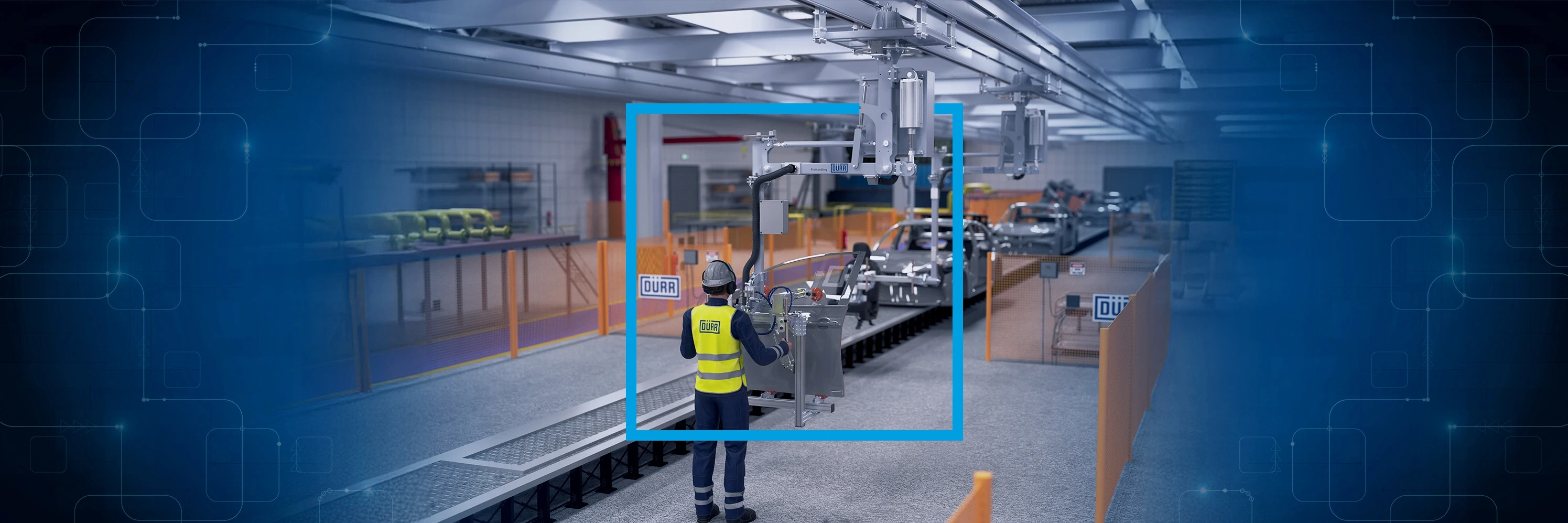

ProHandling: Industrial handlers for increasing the efficiency of your assembly line

We offer industrial handling systems to optimize the efficiency and safety of your assembly line.

Our customer-specific industrial handling systems are ideal for the safe and efficient moving of components that are either very heavy or not stable enough, thereby ensuring a more productive working environment that takes ergonomic requirements into consideration. Discover the full range of possibilities that the advanced industrial handlers from Dürr can offer your process.

For all requirements

Custom-tailored for every purpose, industrial handlers from Dürr are suitable for every performance category. Select the industrial handling system tailored to your needs:

Product range

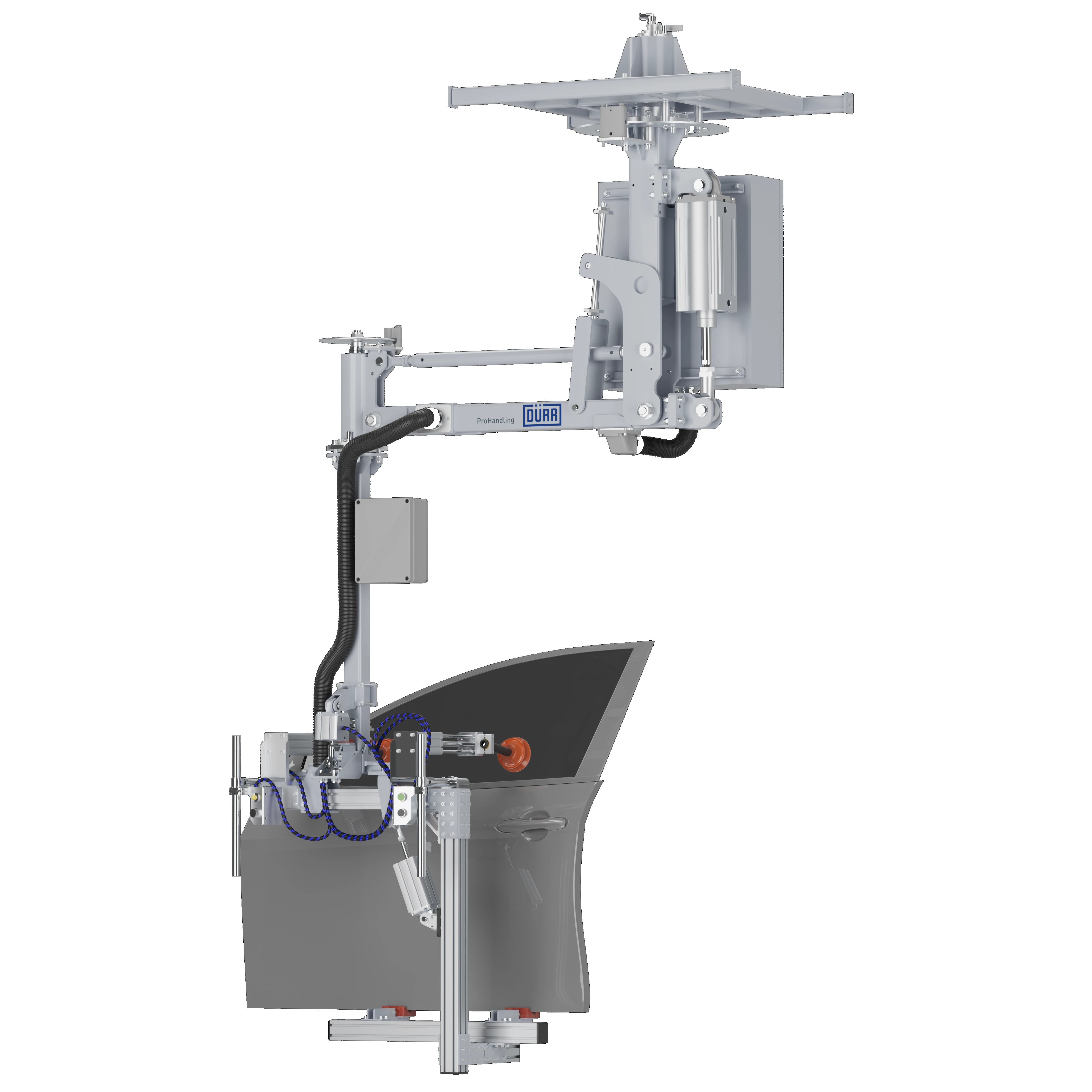

Handling systems from Dürr for light loads are recommended for easily moving weights of up to 80 kilograms. These systems are perfect for performing tasks that require precision and agility, such as assembling components and handling smaller workpieces.

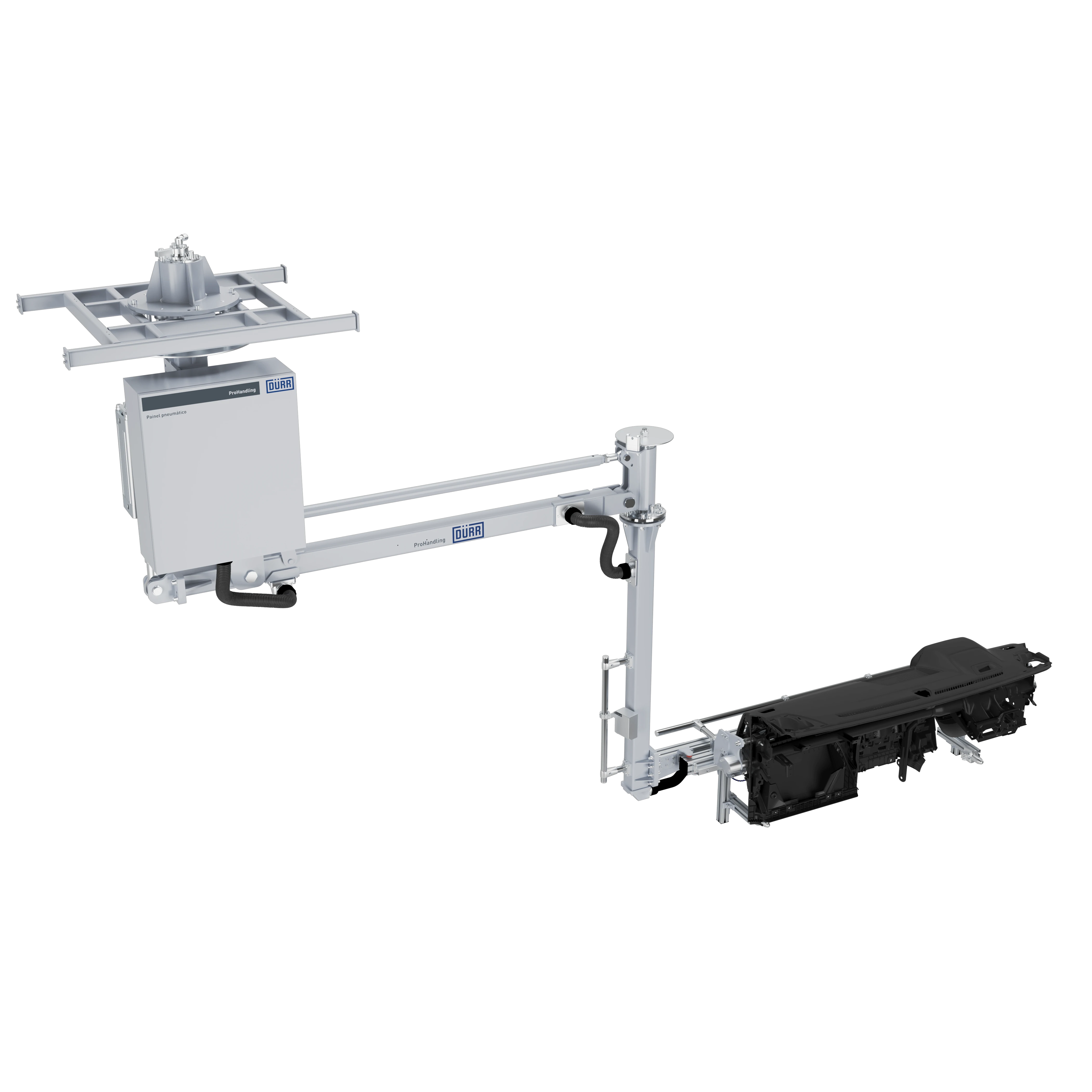

Handling systems from Dürr for medium loads are recommended for moving weights of up to 120 kilograms. They are ideal for applications where the right balance between payload and flexibility is important, such as moving parts on production lines and loading materials in industrial processes.

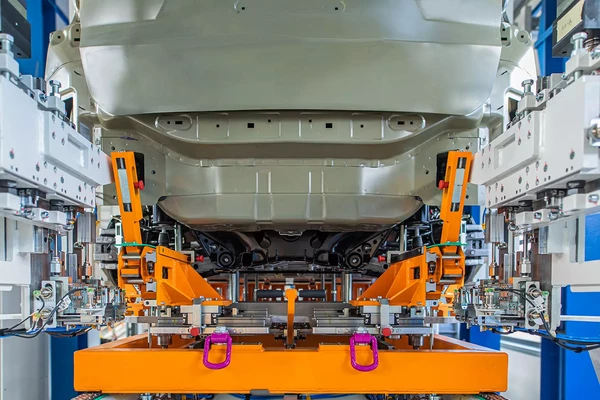

Handling systems from Dürr for heavy loads are recommended for moving weights of up to 200 kilograms. With their rugged design and high load capacity, these systems are ideal for tasks requiring power and strength, such as handling large components or transporting heavy materials in industrial environments.

Technical data

- Maximum load: 200 kg

- Maximum working radius: 2,700 mm

- Operating pressure: 6 bar

- Air consumption: 5 to 10 L/cycle

- Control system: pneumatic and electropneumatic

- Weight of the arm: 155 kg

Advantages

- Safety and ergonomics: Our handling systems meet applicable safety standards and enables operators to work under ideal ergonomic conditions.

- Cost-efficiency: Low maintenance and operating costs for high efficiency and profitability.

- User-defined applications: Adaptable to the customer’s specific application.

- Agility: Thanks to local manufacture and support on site.

- Validation: Carried out in our test center with the participation of the customer.

- Increased productivity: Quicker to implement and simplified processes.

- Standardization and improved quality: The precision of the movements achieved with our handling systems helps to ensure a higher level of quality.

Increased precision and less effort for your operators

With modern manipulators from Dürr, you can ensure compliance with safety and ergonomic standards, provide a safer and healthier working environment for operators, avoid the risk of injury, and guarantee operational efficiency.

Discover how our manipulators can increase the efficiency and safety of your assembly line.

Fill out the form below and contact our team of experts to ensure a safer and more productive working environment for everyone.