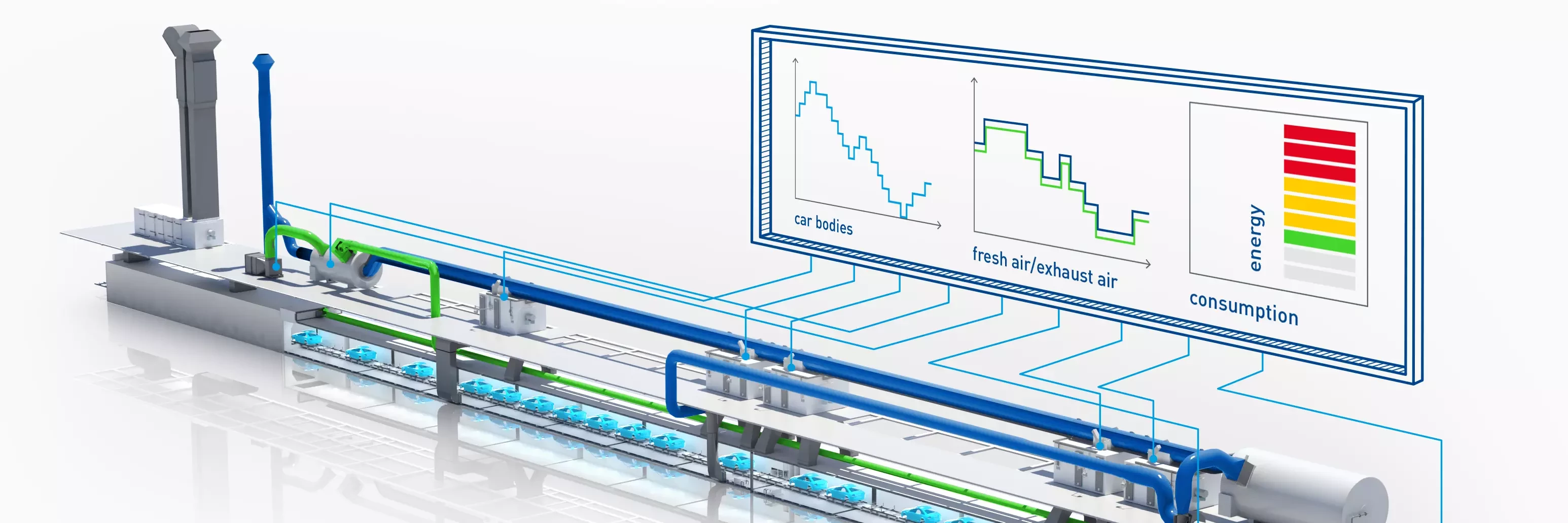

EcoSmart VEC – A fresh and exhaust air control system to provide “energy on demand”

To save energy in the oven, Dürr developed a new, intelligent air management system called EcoSmart VEC. This patent-pending tool controls the fresh and exhaust air volume based on the number of car bodies in the oven.

Besides the spray booth, the oven is the highest energy consumer in the paint shop, with major energy losses due to heat loss via exhaust air. The main reasons for this are break times and production-related fluctuations in capacity such as idle cycles, and faults. Energy losses are substantial even in the ramp-up and commissioning phases.

Using the fresh and exhaust air control system EcoSmart VEC, you supply exactly the amount of energy required in the oven.

In detail, this system has the following features

- Feedforward control with virtual car body tracking: EcoSmart VEC knows where every car body is located in the different oven zones and adapts the fresh and exhaust air accordingly. The system also knows the incoming capacity and acts accordingly

- The oven temperature profile complies exactly with the process specifications at all times

- Product quality is assured (30% less car bodies = 30% less fresh air > constant fresh air volume per car body)

- The variable fresh air volume is supplied to the oven either via the hot boxes or the air seals

- Suitable for many oven variants (direct or indirect oven heating; oven with or without abatement system; straight-through or bottom-entry oven; greenfield or revamp projects)

EcoSmart VEC benefits

- Reduced energy consumption due to process-optimized fresh and exhaust air flow rates

- Automatic process control without manual intervention

- Short payback time

- Top product quality guaranteed – oven temperature profile complies with the process specifications at all times and the fresh air volume per car body is held at a constant level

- Condensate and safety issues taken into account

- Smart control concept due to an intelligent, favorably priced system