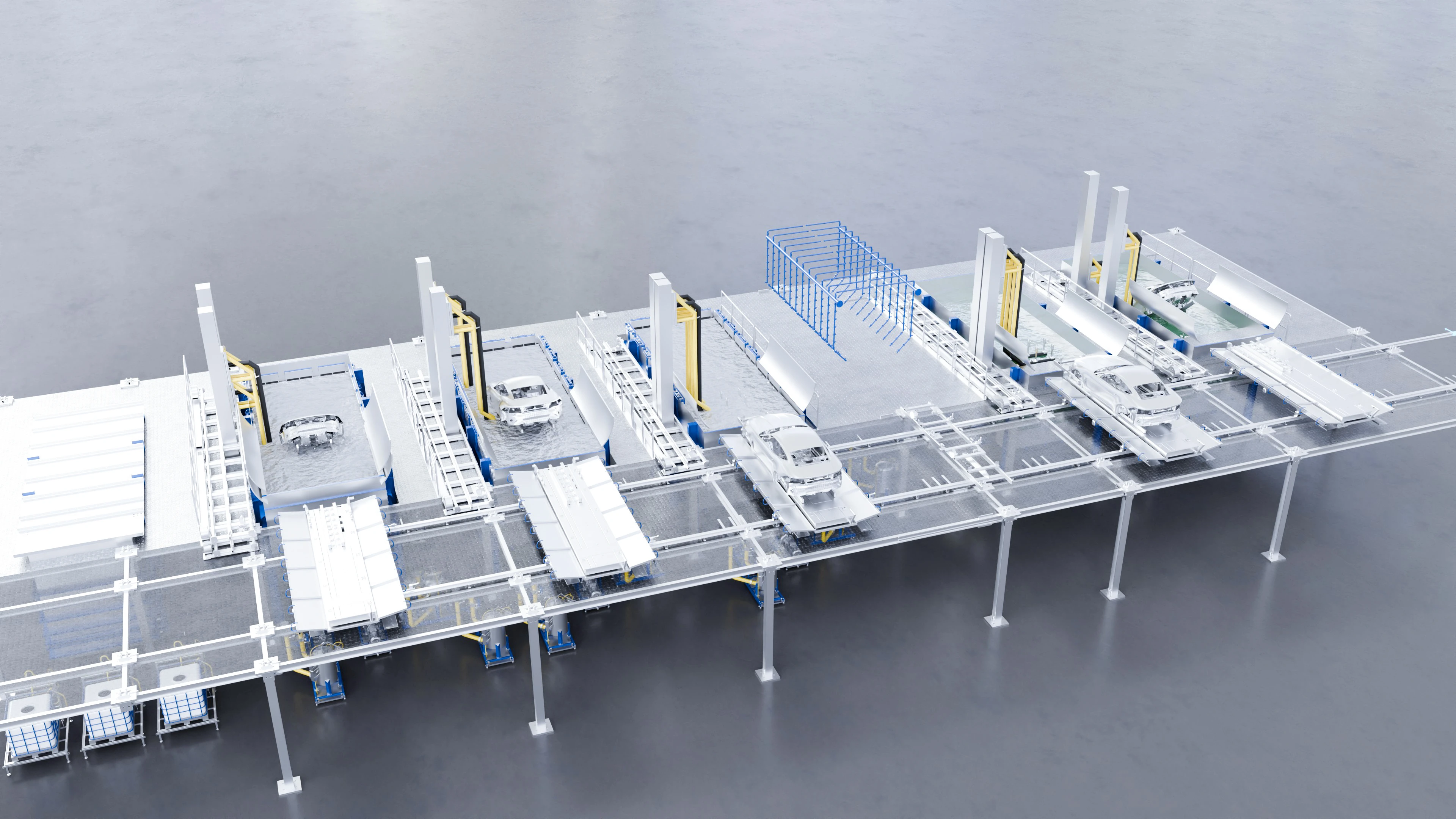

In vehicle painting, pretreatment remains one of the most space-intensive process steps. This is due to the large tanks required for both basic cleaning and electrocoating, which are designed to accommodate the largest car body dimensions and longest process times. Dürr developed the modular EcoProWet pretreatment system, making the process more flexible, compact, and scalable. Previously, the company introduced the EcoProWet PT pretreatment system. Now, it has expanded the system to include the EcoProWet EC cathodic electrocoating system.

Cathodic electrocoating: flexible, compact, and scalable

After pretreatment, the bodies are conveyed to the cathodic electrocoating system. This process ensures that a seamless primer coat is applied to the body’s surfaces, providing corrosion protection and serving as an adhesive base for future topcoats. In contrast to conventional PT/EC systems, EcoProWet is the only system on the market that is scalable and sets new standards in terms of space requirements, sustainability, and investment costs.

The innovative design of the EcoProWet EC system features individual compact basins instead of continuous systems filled with paint. Two independently controllable pendulum towers lift the car bodies from the roller conveyor and gently guide them into the bath. With an immersion angle of up to 60 degrees, automakers can customize the immersion process for different models. Each dip tank supports up to ten units per hour. During the three- to five-minute dip, the paint is energized, forming a thin even coating on the body surface.

The EcoProWet system is ideal for small to medium production capacities. Its modular design allows for staged expansion from 7.5 to 30 units per hour without significant operational disruptions. This enables automotive manufacturers to scale the system according to their production needs, reducing paint and operating costs compared to continuous systems. Additionally, it minimizes the space required for a paint shop while allowing for a flexible layout.