- durr.com

- >

- Products

- >

- Environmental technology

- >

- Exhaust gas and air pollution control

- >

- Oxi.X – Thermal processes

- >

- Oxi.X – Regenerative thermal oxidation

- >

- Oxi.X RL – Regenerative thermal oxidizer

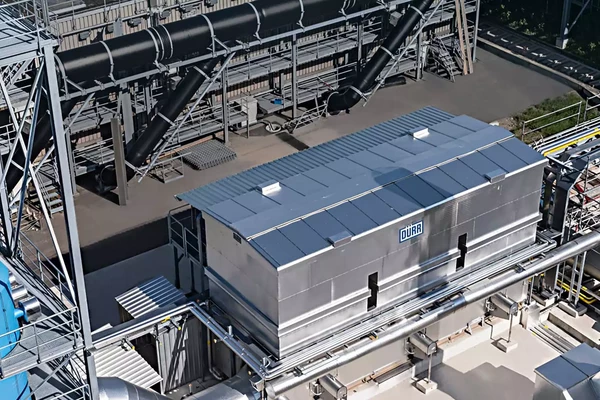

Oxi.X RL – The RTO with a rotary valve

The Oxi.X RL is a unique regenerative thermal oxidizer with a rotary distributor valve that is capable of removing more than 99% of volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and odors from industrial exhaust gas flows. The Oxi.X RL is based on the thermal process.

Oxi.X RL benefits

The unique rotary valve system and radial ceramic heat exchanger beds make the Oxi.X RL the most compact system of its kind on the market. The unit is pre-fabricated and assembled in the factory. This allows it to be shipped, installed, and commissioned in the shortest possible time. The electric distributor valve eliminates the need for hydraulic or pneumatic dampers, actuators, and limit switches. This reduces the complexity of the system and the amount of maintenance required. An air-conditioned control room is provided on each Oxi.X RL skid which houses the main control panel and the frequency converter. As a result, most of the wiring can be installed and the system tests can be completed before the system leaves the factory.

The benefits of using an Oxi.X RL air pollution control system are as follows:

- Easy to install

- Compact design

- Low maintenance

- Low operating expenditure

- No hydraulic or pneumatic valves needed

Operating principle Oxi.X RL

The Oxi.X RL has twelve separate ceramic heat exchanger beds that are arranged radially over a proprietary distributor valve. Incoming contaminated air enters the media beds through the base of the Oxi.X RL and is drawn upwards through five of the beds which have been pre-heated.

The air is heated as it rises and enters a combustion chamber at the top of the system where a burner provides any additional energy needed to complete the oxidation process. The pollutants are oxidized at high temperatures and converted into CO2 and H2O. Hot, clean exhaust gas is then drawn downwards through the five adjacent ceramic beds where the thermal energy is transferred to the blocks before the clean air is released into the atmosphere.

The two “spare” beds help to prevent cross contamination between the inlet and outlet sections and ensure that the Oxi.X RL unit is highly efficient. Up to 95% of the thermal energy required for the oxidation process is recovered internally which keeps the consumption of fuel by the burner to a minimum.

Application areas Oxi.X RL

The Oxi.X RL system can be used in a wide variety of industries including:

- Chemical

- Pharmaceutical

- Petrochemical

- Carbon fiber

- Food

- Composites/textiles

- Fire testing facilities

- Foundries

- Glass

- Painting and surface treatment

- Printing and coating

- Rubber/latex

- Semiconductors

- Waste treatment/recycling

- Timber

Technical specifications Oxi.X RL

Dürr Oxi.X RL regenerative thermal oxidizers are available in pre-engineered sizes for exhaust gas flows from 25 000 SCFM to 80 000 SCFM (40 000 Nm3/h to 126 000 Nm3/h). They can treat exhaust gases containing pollutant concentrations from <1g/Nm3 to 10g/Nm or up to 25% LEL (lower explosive limit).The Oxi.X RL has an efficiency level of more than 99% and can remove the following pollutants from exhaust gases in industrial processes:

- Aliphatic and aromatic hydrocarbons

- Hazardous air pollutants (HAPs)

- Odors

Construction Oxi.X RL

The compact, standardized Oxi.X RL Air Pollution Control System, which creates a special airflow through a rotating distributor in a single container, is available in various sizes. The system consists of twelve separate ceramic heat exchanger beds, which are arranged radially above a rotary distributor valve. The Oxi.X RL comes as standard with a state-of-the-art burner control system consisting of a burner and a patented rotor. The Oxi.X RL is pre-assembled on transport frames and shipped in as few sections as possible to keep the installation time and costs to a minimum.

Carl-Benz-Str. 34

74321 Bietigheim-Bissingen

Germany

26801 Northwestern Highway

48033 Southfield, MI

United States