News

Find all information on Dürr's recent customer projects, new products, events and other press releases below. If you have any questions on the publications or require further information please get in touch with the contact person indicated.

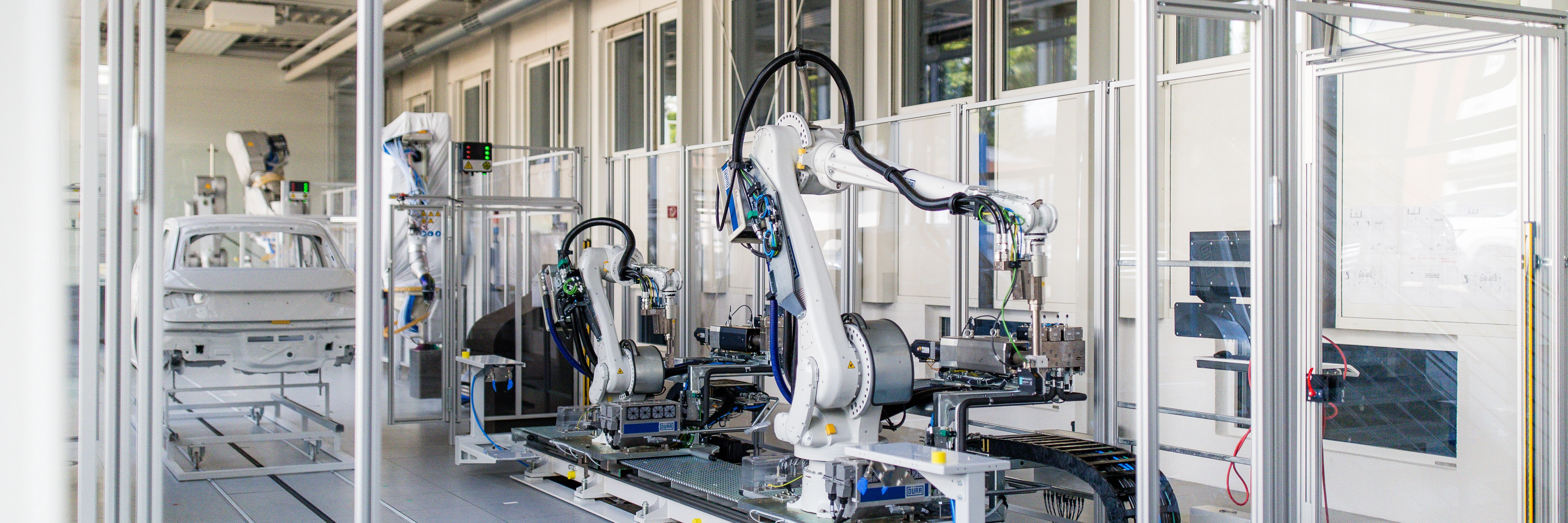

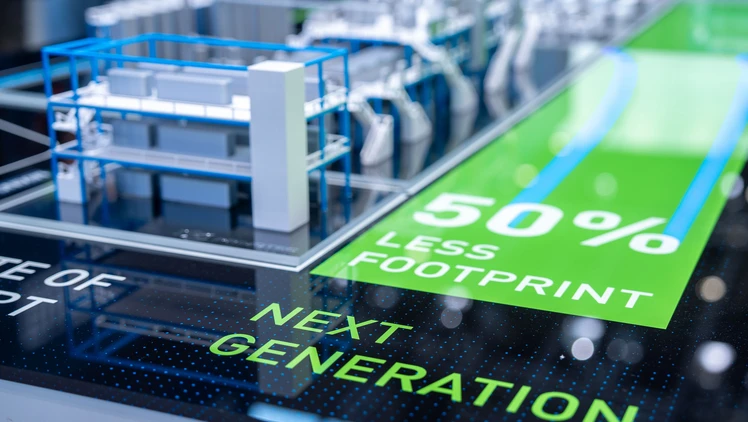

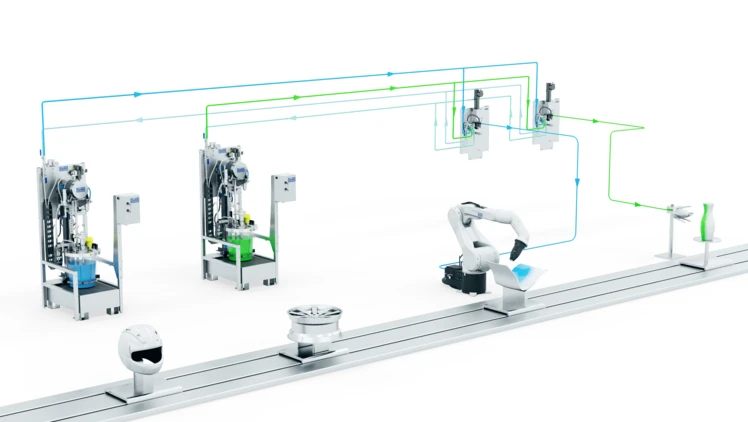

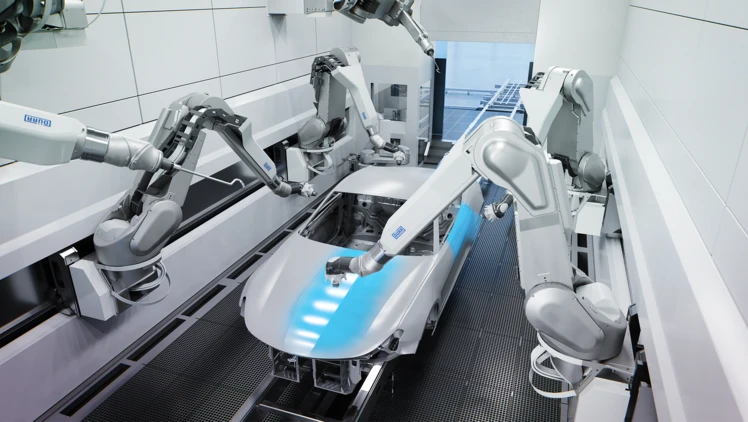

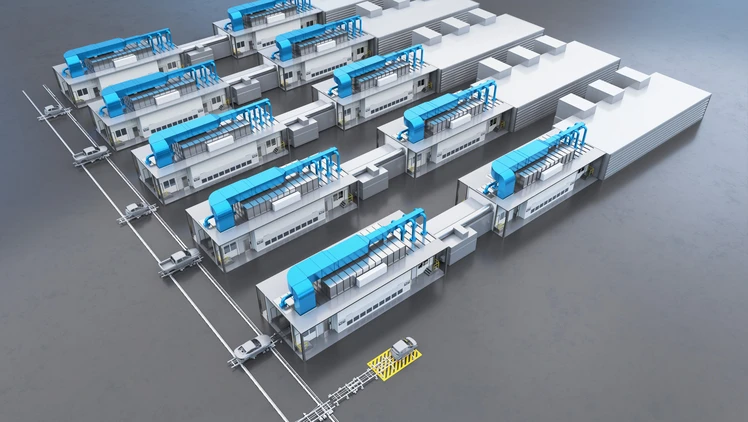

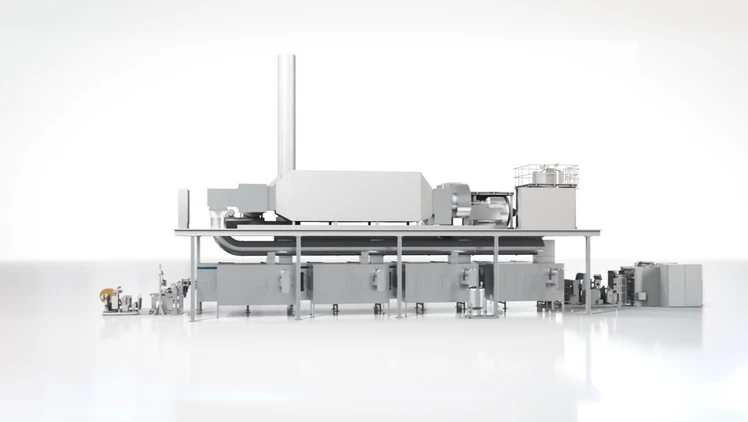

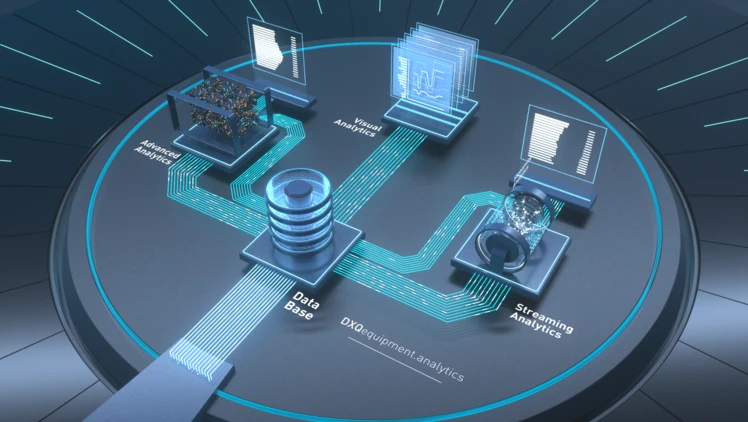

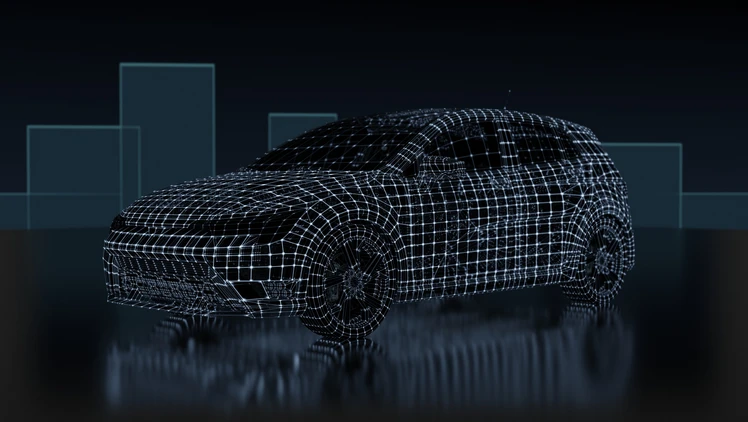

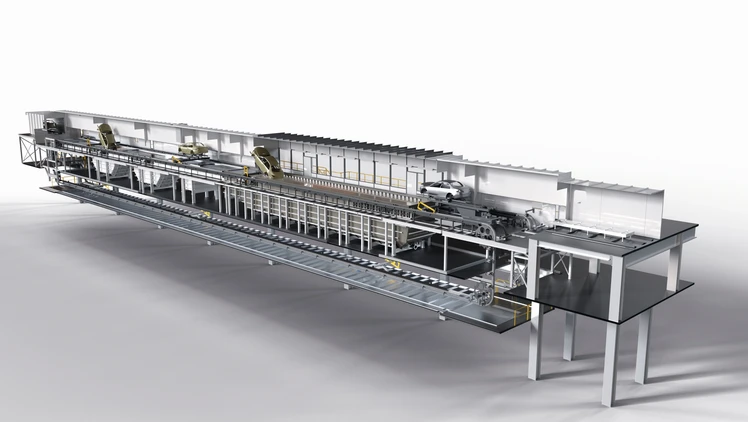

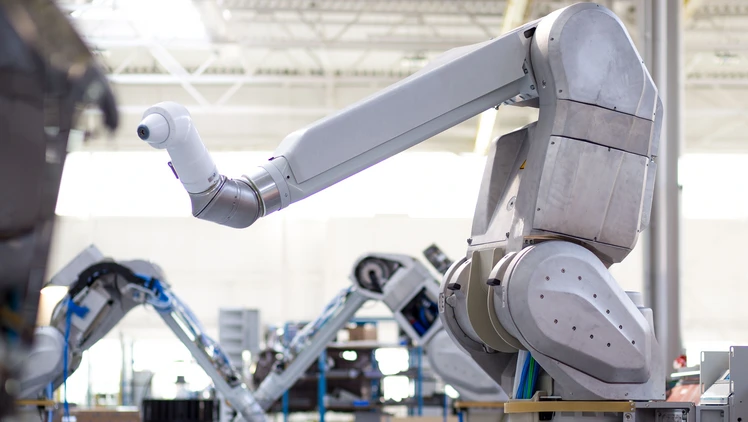

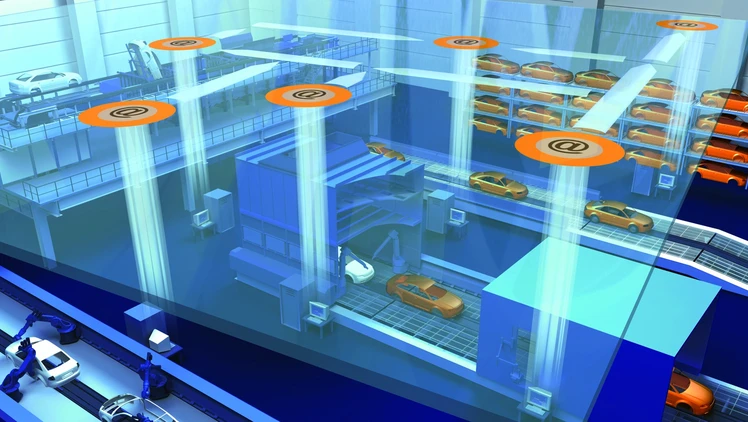

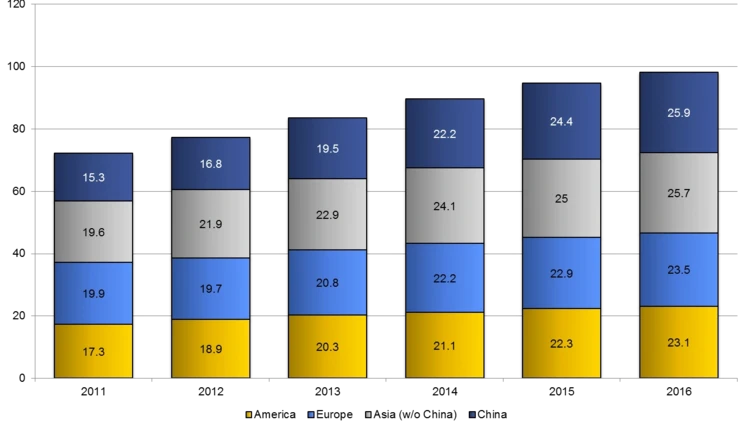

The Dürr Group is one of the world's leading mechanical and plant engineering firms with particular expertise in the technology fields of automation, digitalization, and energy efficiency. Its products, systems, and services enable highly efficient and sustainable manufacturing processes – mainly in the automotive industry and for producers of furniture and timber houses, but also in sectors such as the chemical and pharmaceutical industries, medical devices, electrical engineering, and battery production. In 2024, the company generated sales of €4.7 billion. The Dürr Group has around 18,400 employees and 139 business locations in 33 countries. As of January 1, 2025, the former divisions Paint and Final Assembly Systems and Application Technology were merged to form the new Automotive division. Since then, the Dürr Group has been operating in the market with four divisions:

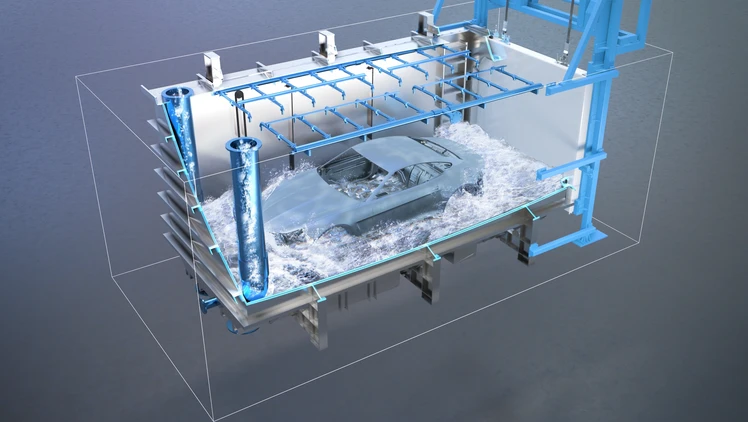

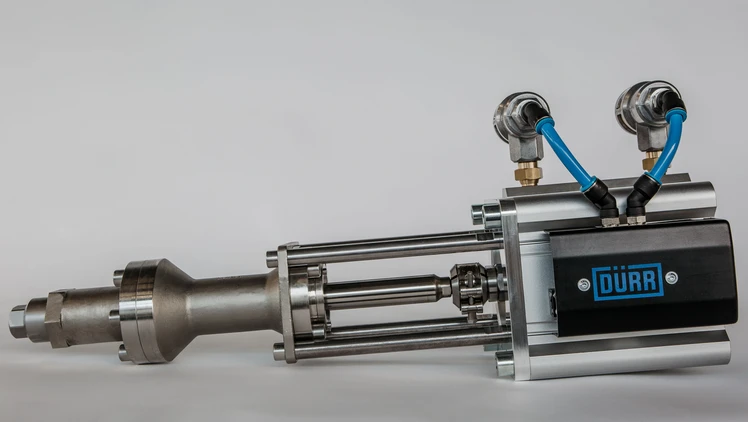

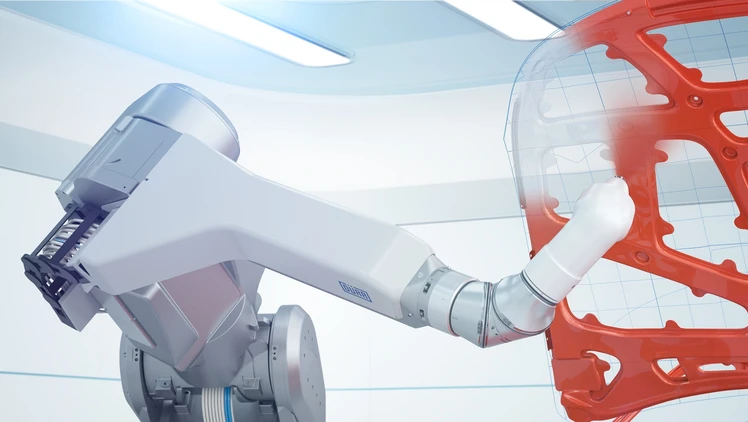

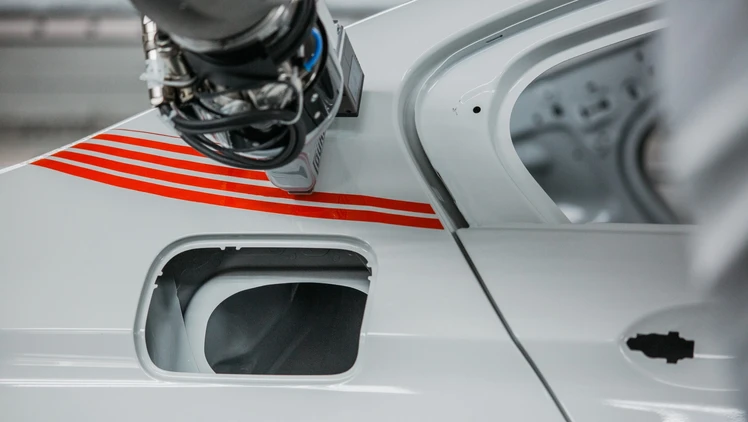

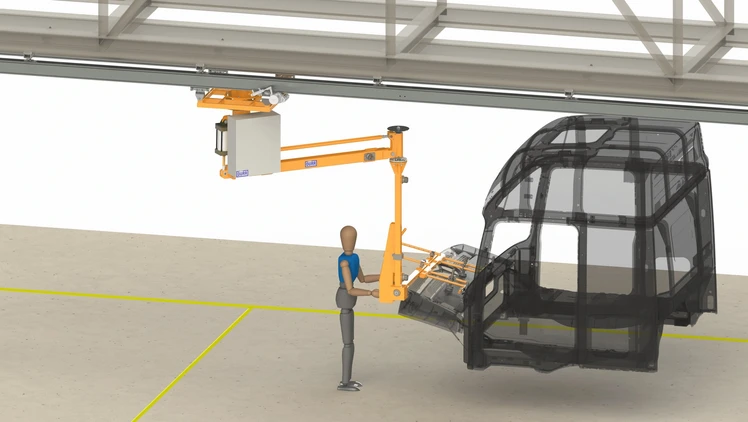

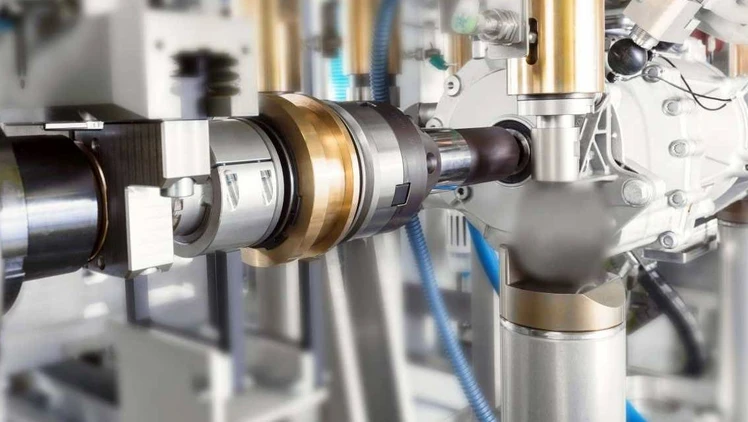

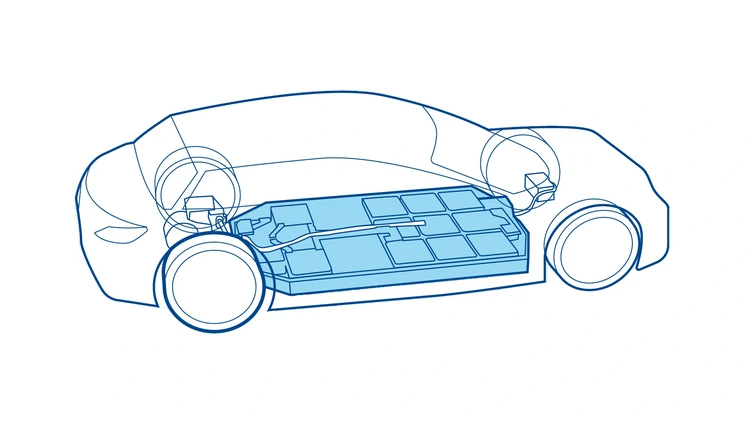

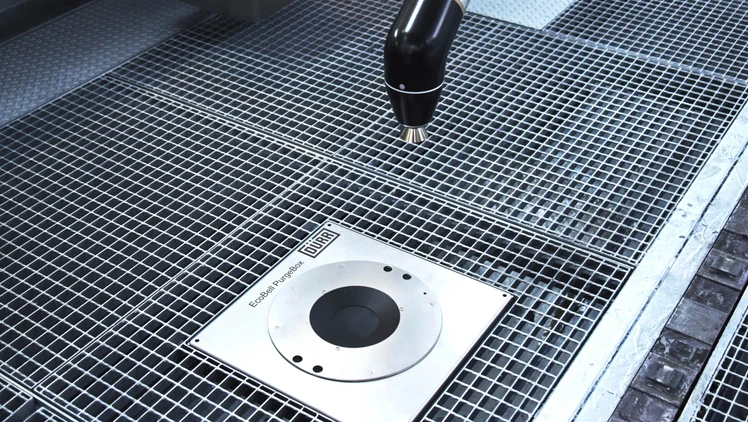

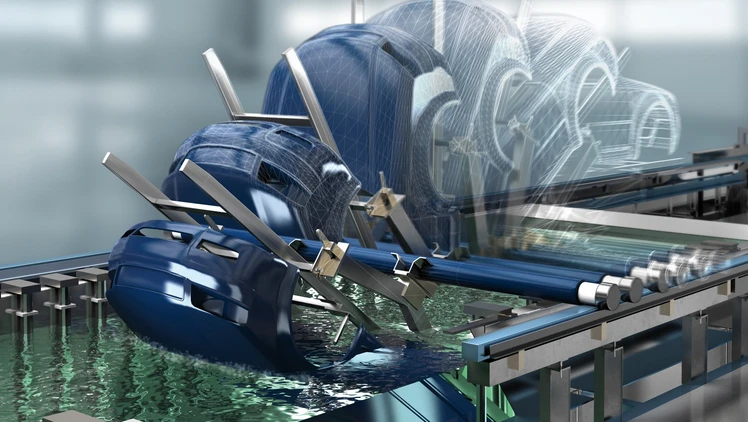

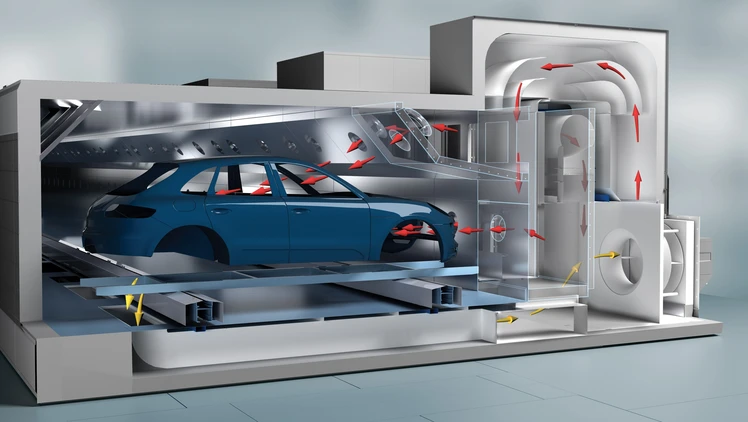

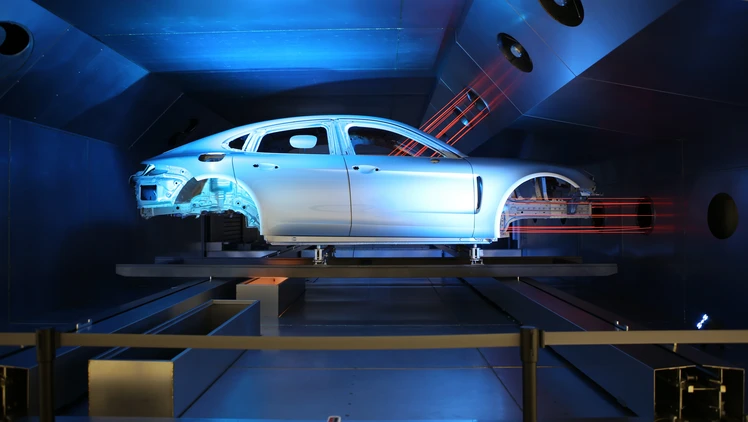

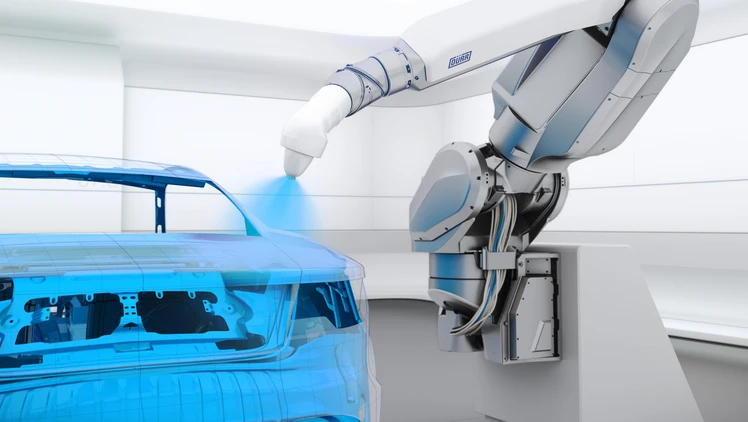

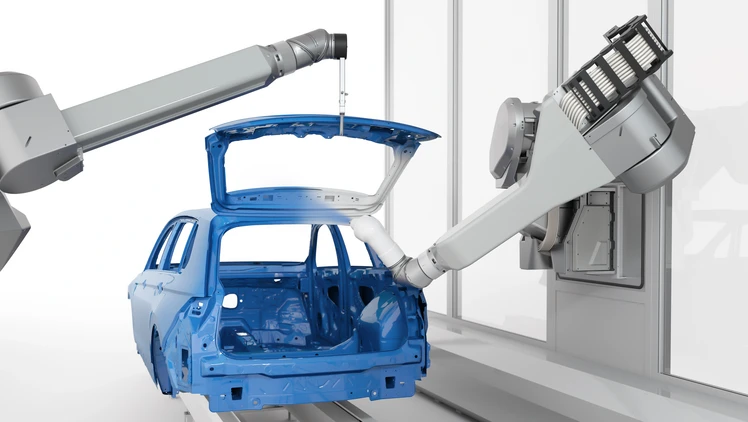

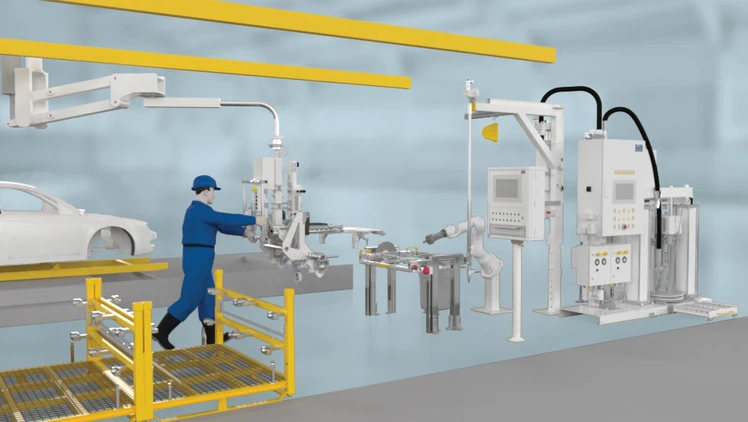

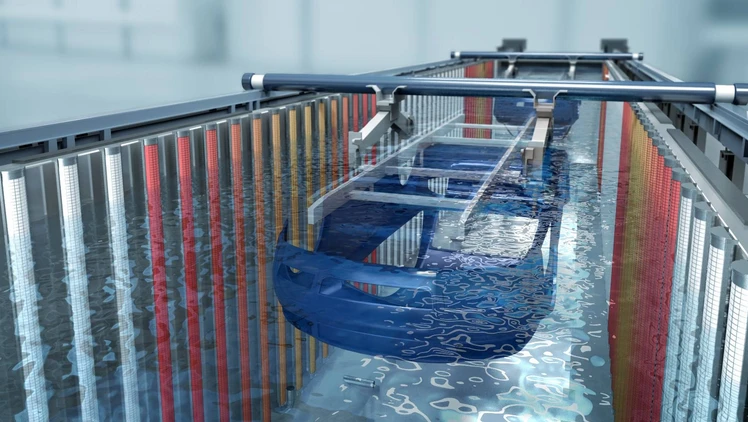

- Automotive: painting technology, final assembly, testing and filling technology

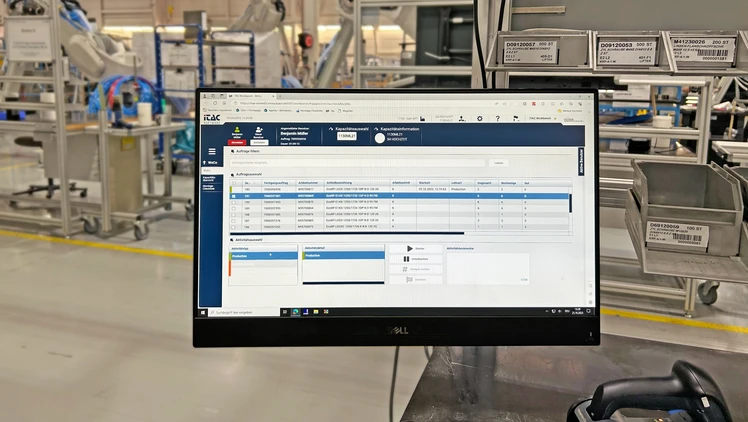

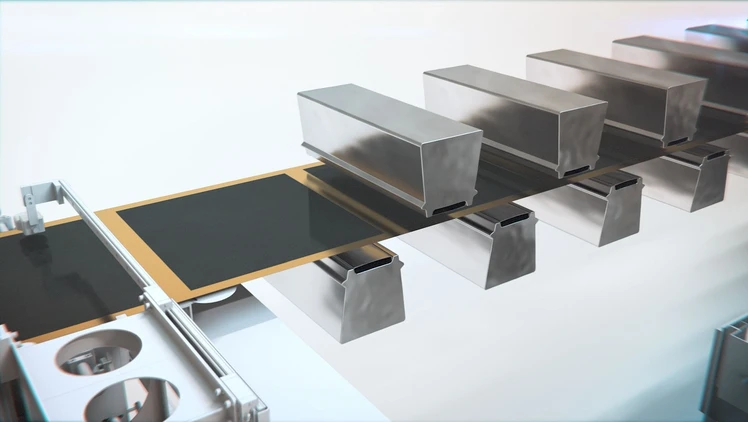

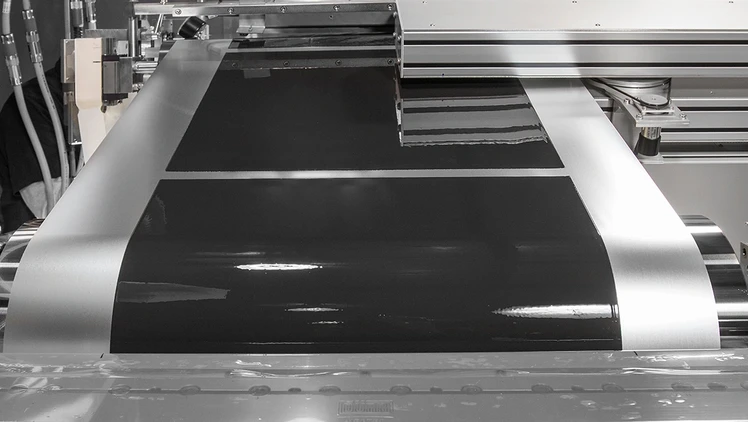

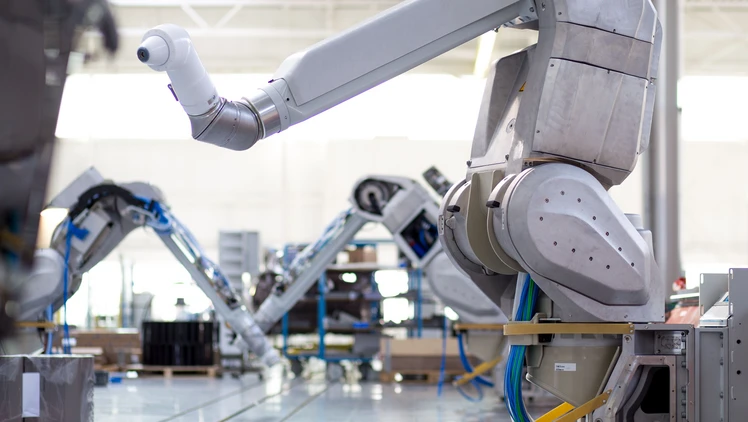

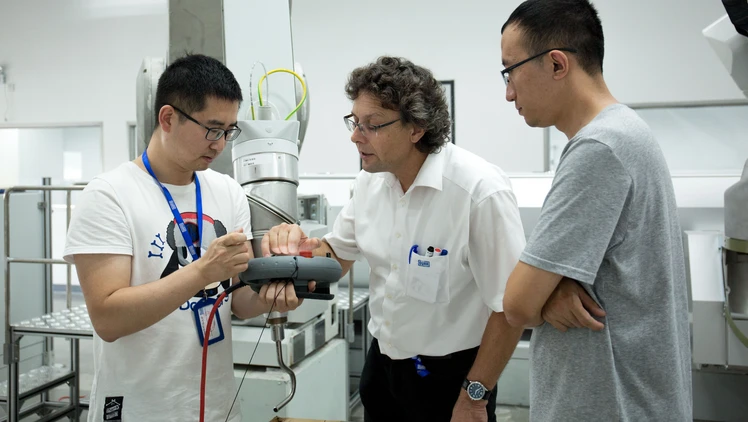

- Industrial Automation: automated assembly and test systems for automotive components, medical devices, and consumer goods as well as balancing technology solutions and coating systems for battery electrodes

- Woodworking: machinery and equipment for the woodworking industry

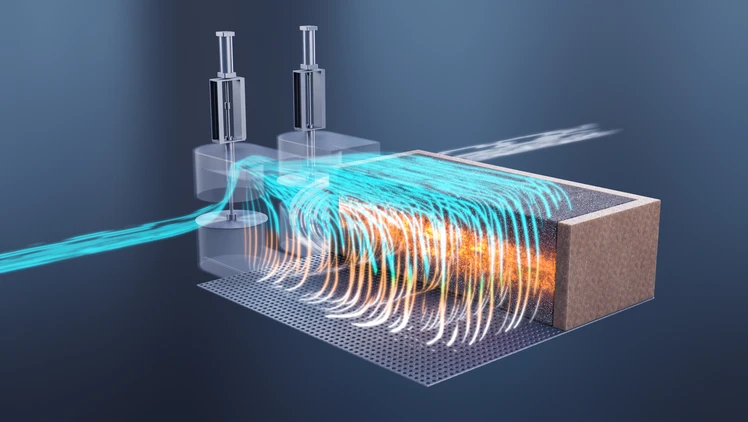

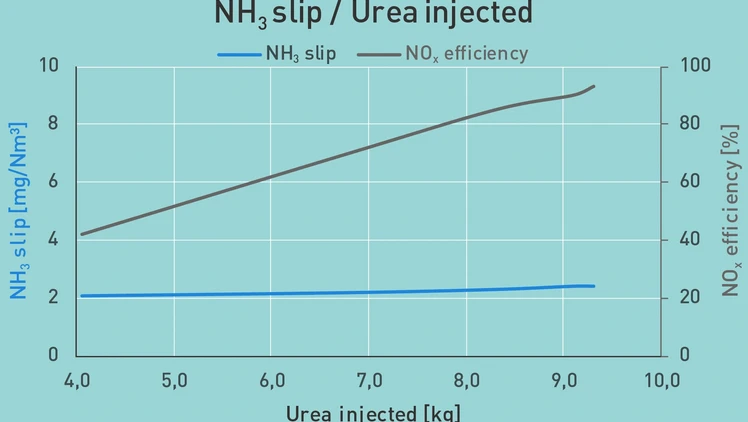

- Clean Technology Systems Environmental: air pollution control and noise abatement systems